Solid Carbide Downcut Spiral Bits - DLCS Chrome Coating - Long life

192.41

THE ULTIMATE TECHNOLOGY FOR INDUSTRIAL CNC TOOLS

DLCS is a modified diamond-like carbon coating with enhanced load bearing capacity. A hard, durable metal-based layer (chromium nitride) provides an higher hardness surface and increases the resilience of the superposed, tribologically effective carbon coating. Coating prevents high heats which is detrimental to cutting tool performance and will remain fully effective after use.

DLCS CHROME COATING

provides 3 times longer life than uncoated tools!

provides 3 times longer life than uncoated tools!

Extreme Coating Hardness >HV 2.500

Offers impressive hardness on cutting areas of the tool and superb protection against abrasive wear and stress resistance.

Minimal coating thickness μm 2-4

The minimal micron coating guaranteed perfect sharpen edges for high cutting quality.

Offers impressive hardness on cutting areas of the tool and superb protection against abrasive wear and stress resistance.

Minimal coating thickness μm 2-4

The minimal micron coating guaranteed perfect sharpen edges for high cutting quality.

The lowest coefficient of friction 0,1-0,2

Very good running-in and low friction losses. Reduction of sticking. Ideal for high speeds in Nesting applications.

High Working Temperature

Less overheating! The coating guarantees working temperature up to 400° preserving the cutting edges from wear.

TECHNICAL FEATURES:

• Premium quality HWM.

• 1+1 spiral cutting edges [Z1+1].

• 2+2 spiral cutting edges (Z2+2).

• 3+3 spiral cutting edges [Z3+3].

• Provide an excellent finish on both the upper and the lower side of the workpiece.

Test performed in U.S. with ½” solid carbide compression spiral bit

Machine: Felder Profit H10 Nested Base/Overhead CNC Router.

Working Parameters: RPM = 18,000 - Feed = 20 mts/minute.

Material: 19mm Melamine Chipboard.

Application: Nesting Full Dimensioning.

Performance: DLCS coated bit cut 165 melamine panels. Uncoated bit cut 56 melamine panels.

Details

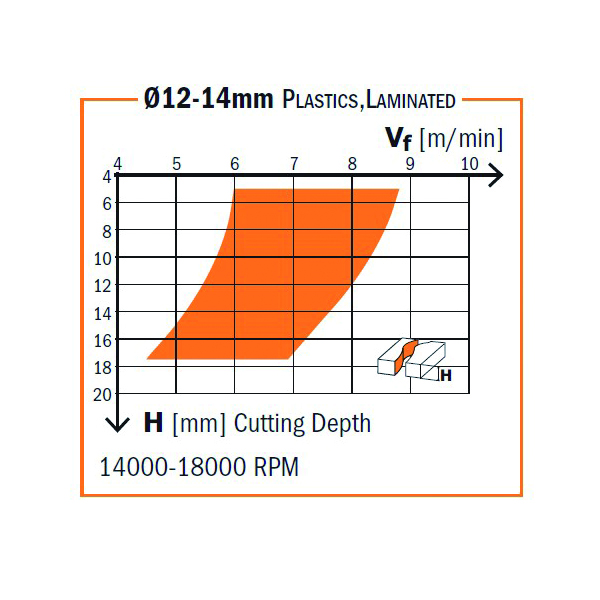

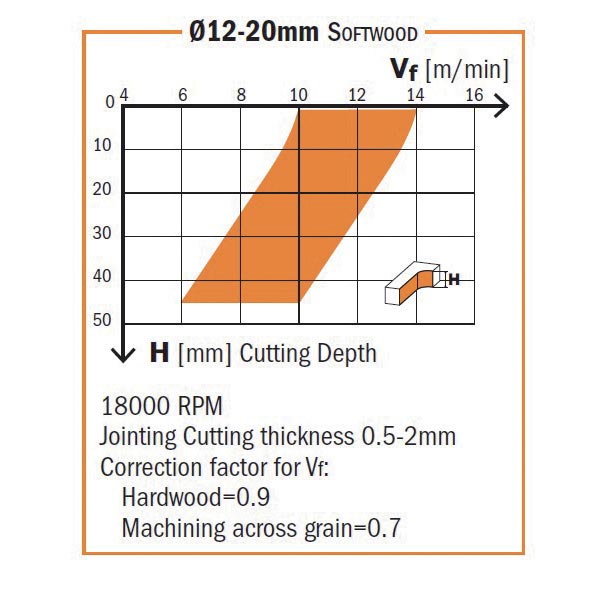

Used for efficient contour cutting, end-trimming and

panel sizing on solid wood, wood composites, plastic

materials and laminates at high feed speed. Ensure

to properly clamp workpieces.

Can be used on machining centres, point-to-point

boring machines, CNC routers and hand-held routers

equipped with chucks or adaptors.

Download

Variations

Filter

| Item Code | D | I | L | S | Z | MAT | RH-LH |

|---|---|---|---|---|---|---|---|

|

192.007.41

|

6.35 | 19.05 | 50.8 | 6.35 | 2 | HWM | RH |

|

192.008.41

|

6.35 | 25.4 | 63.5 | 6.35 | 2 | HWM | RH |

|

192.503.41

|

9.52 | 31.75 | 82.5 | 12.7 | 2 | HWM | RH |

|

192.505.41

|

12.7 | 31.75 | 76.2 | 12.7 | 2 | HWM | RH |

|

192.506.41

|

12.7 | 38 | 89 | 12.7 | 2 | HWM | RH |

|

192.507.41

|

12.7 | 50.8 | 101.6 | 12.7 | 2 | HWM | RH |