Company

Who we are

Over the years, CMT has been making massive investments in the most advanced technology in CNC machine equipment and in innovative software to manufacture woodworking cutting tools.

Furthermore, CMT has hired highly skilled engineers and operators to manage the production operations. The result, the entire woodworking cutting tool manufacturing process is completely automated.

CMT products are manufactured for industrial applications and woodworking cutting tools are utilized by world leading furniture makers, kitchen manufacturers and CNC machinery manufacturers.

Because of our intense investment in advanced production technology, CMT is able to offer industrial tooling at an affordable price to an ever growing following of cabinet makers, contractors and woodworkers as well our manufacturing customers.

The Udine production facility, a state-of-the-art site dedicated to crafting high-quality circular blades, proudly upholds the tradition of 100% Made in Italy excellence.

Here, technical expertise and managerial know-how come together to develop and patent cutting-edge solutions celebrated for their precision engineering and outstanding cutting performance.

This unwavering commitment to innovation and quality has established the Udine facility as a benchmark in the industry.

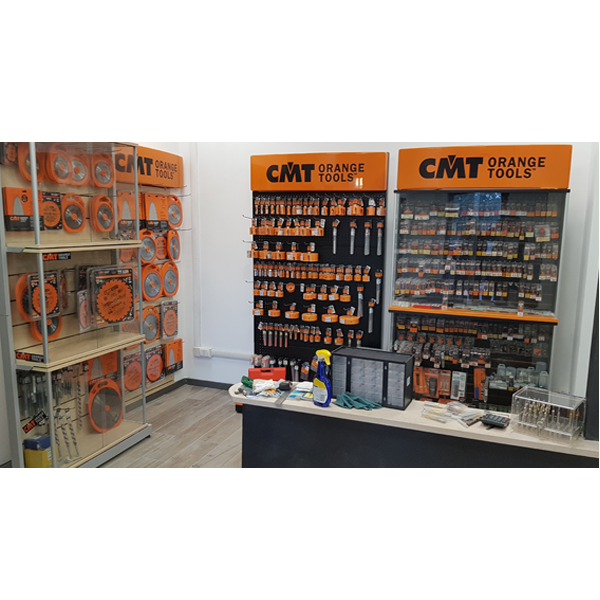

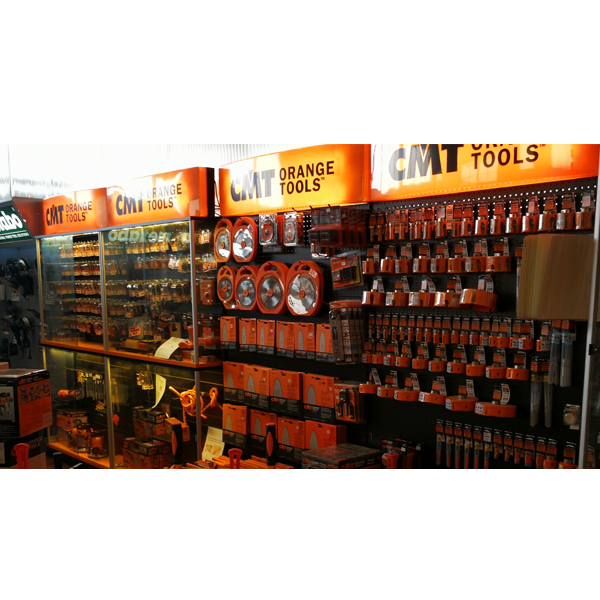

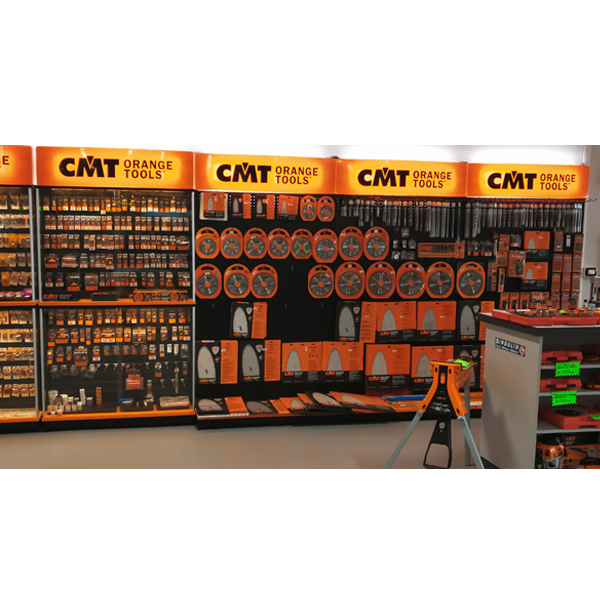

The CMT Orange Tools® brand is known throughout the world woodworking community as the premium brand of woodworking cutting tools.

The CMT mission is to continually improve our quality while offering the woodworking world the finest quality at affordable prices.

We are proud to be CMT Orange Tools!

Why CMT

OUR TRADEMARK COLOR ORANGE

As the story goes, we began small. We also put orange color surface coating on our tools, then we put our tools on the market and soon our orange tools were all over the world.

Now, any woodworker anywhere in the world can tell you that orange tools means CMT, and that CMT means quality. Here at CMT we know we produce quality.

Now, any woodworker anywhere in the world can tell you that orange tools means CMT, and that CMT means quality. Here at CMT we know we produce quality.

You should too. That’s why we have trademarked the color orange on woodworking tools - it’s your guarantee that you are getting a genuine high-quality CMT product.

DESIGN

Everything starts with a clear idea and having the potential to express it. We have both.

At CMT, our technical department uses the best of both worlds – computer technology and hands-on experience - to engineer and design each tool so that it performs flawlessly each time you use it, and to guarantee that you’ll be using it for a long, long time.

At CMT, our technical department uses the best of both worlds – computer technology and hands-on experience - to engineer and design each tool so that it performs flawlessly each time you use it, and to guarantee that you’ll be using it for a long, long time.

MATERIALS

Turning a design into a finished product means finding the right material that will do the job and that lives up to the specifications set out in the design - quality performance from the final product depends on it.

When it comes to selecting raw materials, we don’t cut corners. At CMT, we know that high quality tools come only from high quality raw materials, so we use only solid bar stock steel and specially formulated micrograin carbide to manufacture our bits and blades.

MANUFACTURING

Like we said, it’s not just what you do but how you do it.

Over the years we have continuously invested in the latest technology in CNC machining equipment and innovative software to manufacture our tools.

Over the years we have continuously invested in the latest technology in CNC machining equipment and innovative software to manufacture our tools.

The result is that now our entire manufacturing process, from turning and milling the steel shanks to brazing and sharpening the carbide cutting tips, is completely automated.

And since a machine is only as intelligent at the person using it, everything is operated by specifically trained operators.

THE FINAL TOUCH

A tool simply wouldn’t be a CMT tool if it didn’t have the trademark orange color non-stick PTFE coating on it. This unique industrial- strength surface coating is designed to withstand the physical stresses the tool undergoes during use while protecting it from residue build-up and burning.

And we really like the orange color too.

QUALITY CONTROL

Nobody’s perfect, but we’re trying.

CMT uses rigorous quality control programs and the latest generation machining equipment to ensure that each bit has been manufactured with precision and accuracy and that it will give the long-lasting performance you expect from a CMT orange tool. Our tools are manufactured in compliance with European Standard EN 847 published and enforced by the CEN (European Committee for Standardisation).

CMT uses rigorous quality control programs and the latest generation machining equipment to ensure that each bit has been manufactured with precision and accuracy and that it will give the long-lasting performance you expect from a CMT orange tool. Our tools are manufactured in compliance with European Standard EN 847 published and enforced by the CEN (European Committee for Standardisation).

WE RECYCLE

CMT filters and purifies its water using a reverse osmosis system located inside the plant. Also the oil used in grinding and machining our tools must be clean and absolutely free of contaminants. Clean oil, after enough use, gets dirty, so we filter and reprocess dirty oil on the premises.

This is our way of guaranteeing the quality of the oil we use, as well as contributing to help protect the environment.

Logistics

Technology and quality in the production process

CMT offers a wide product range with over 7000 different standard tools, but that still isn’t enough to achieve 100% customer satisfaction.

It’s a top priority to process orders and ship the same day.

That’s why CMT factories worldwide are equipped with 20+ automated vertical storage systems programmed to expedite and simplify order and delivery.

The tools you need, in-stock and ready for prompt shipment within 24 hours.

The tools you need, in-stock and ready for prompt shipment within 24 hours.

What does this translate to for customers? Quick and efficient service exceeding customer satisfaction and branding our success.

Our strategy is functionality. Our promise is quality. Always on time.