On-site Job Construction - XTREME

286.XTREME

|

|

LASER-CUT PREMIUM QUALITY STEEL PLATE BODY |

|

|

LASER-CUT SOUND DAMPENING SLOTS |

|

|

TENSIONING RING (∅250mm and above) |

|

TRI-METAL BRAZING |

|

INDUSTRIAL CHROME CARBIDE |

|

PRECISION MIRROR FINISH SHARPENING |

|

|

HARD LAQUERING |

.png) |

CMT XTREME BALANCING* |

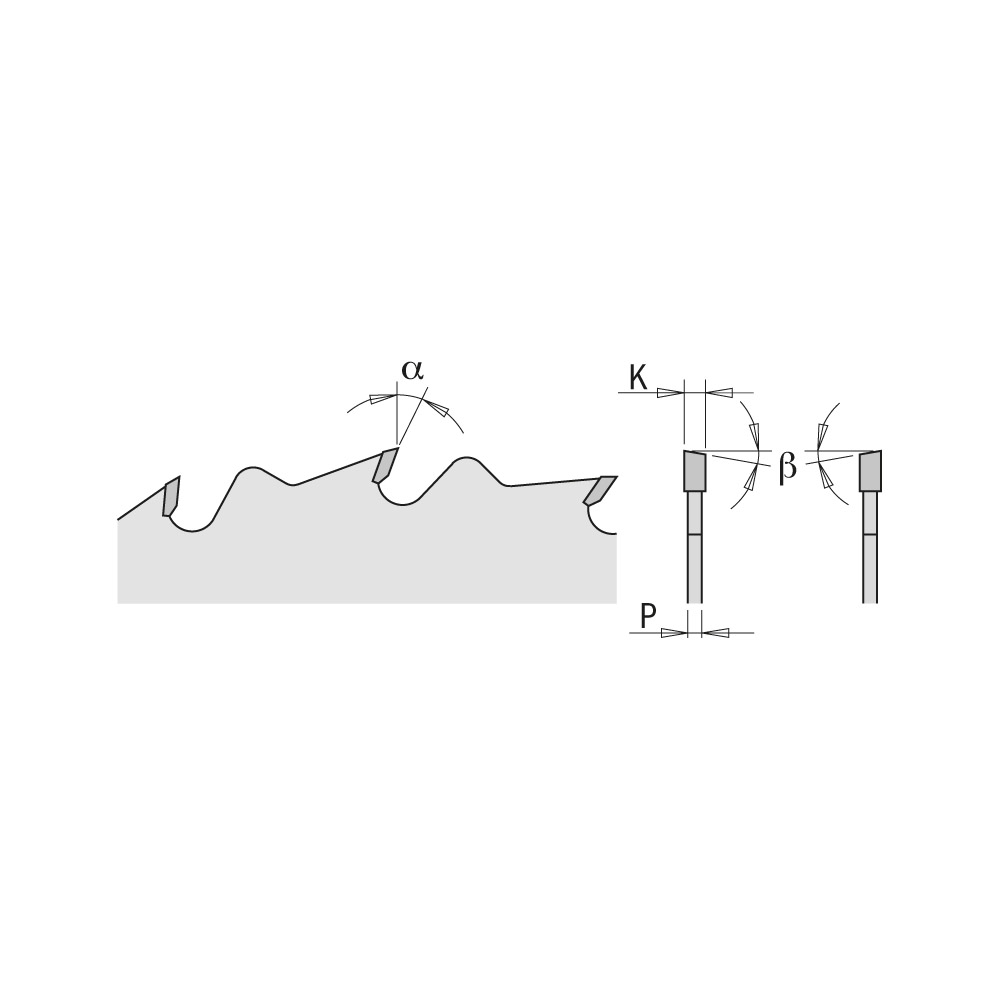

| Item Code | Description | D | B | PH | Z | K | P | α | β |

|---|---|---|---|---|---|---|---|---|---|

|

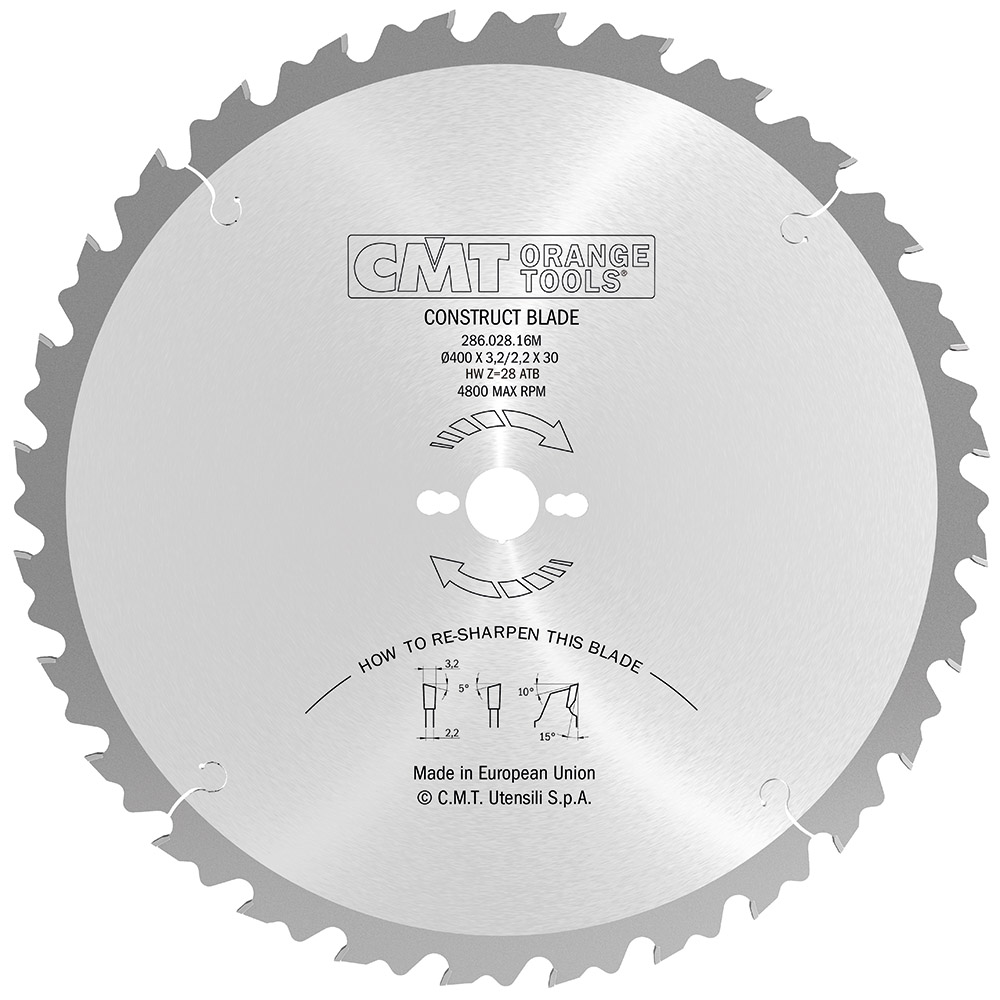

286.028.16M

|

400 | 30 | COMBI3 | 28 | 3.2 | 2.2 | 15 | ATB 5 | |

|

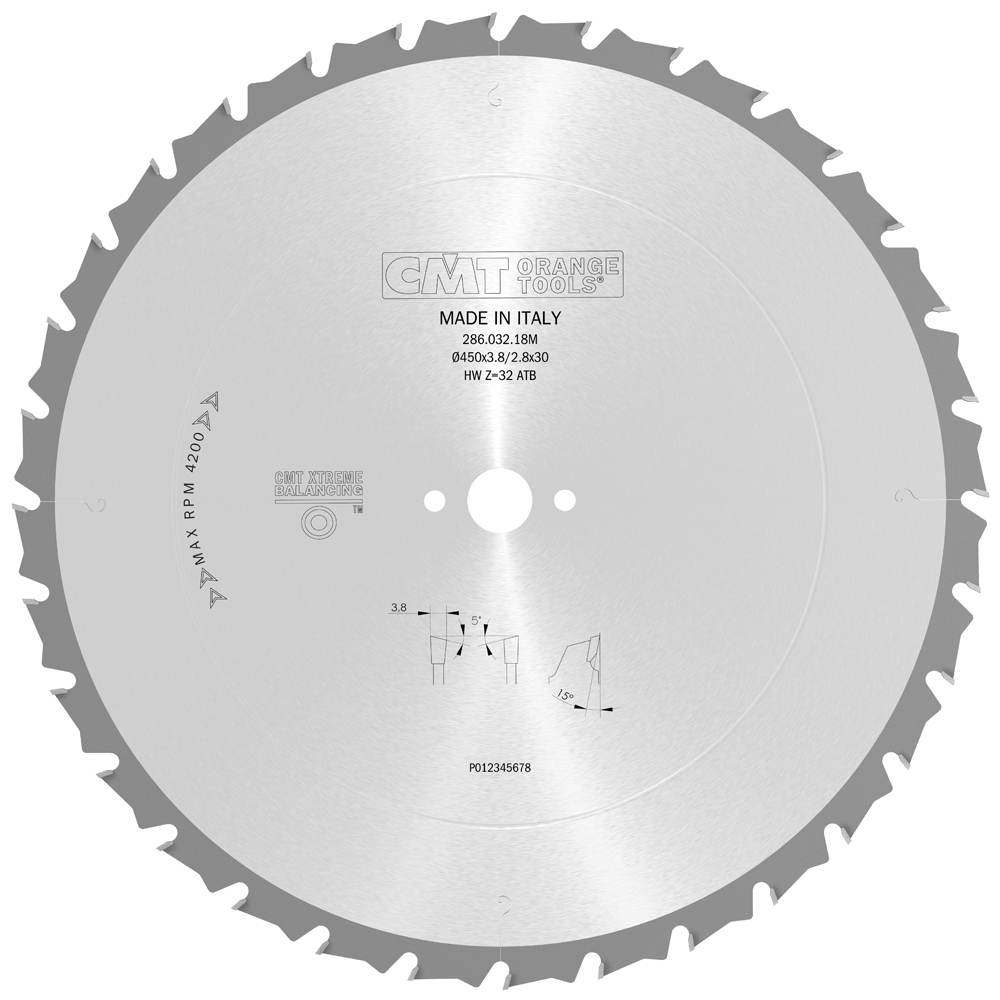

286.032.18M

|

450 | 30 | 2/10/60 | 32 | 3.8 | 2.8 | 15 | ATB 5 | |

|

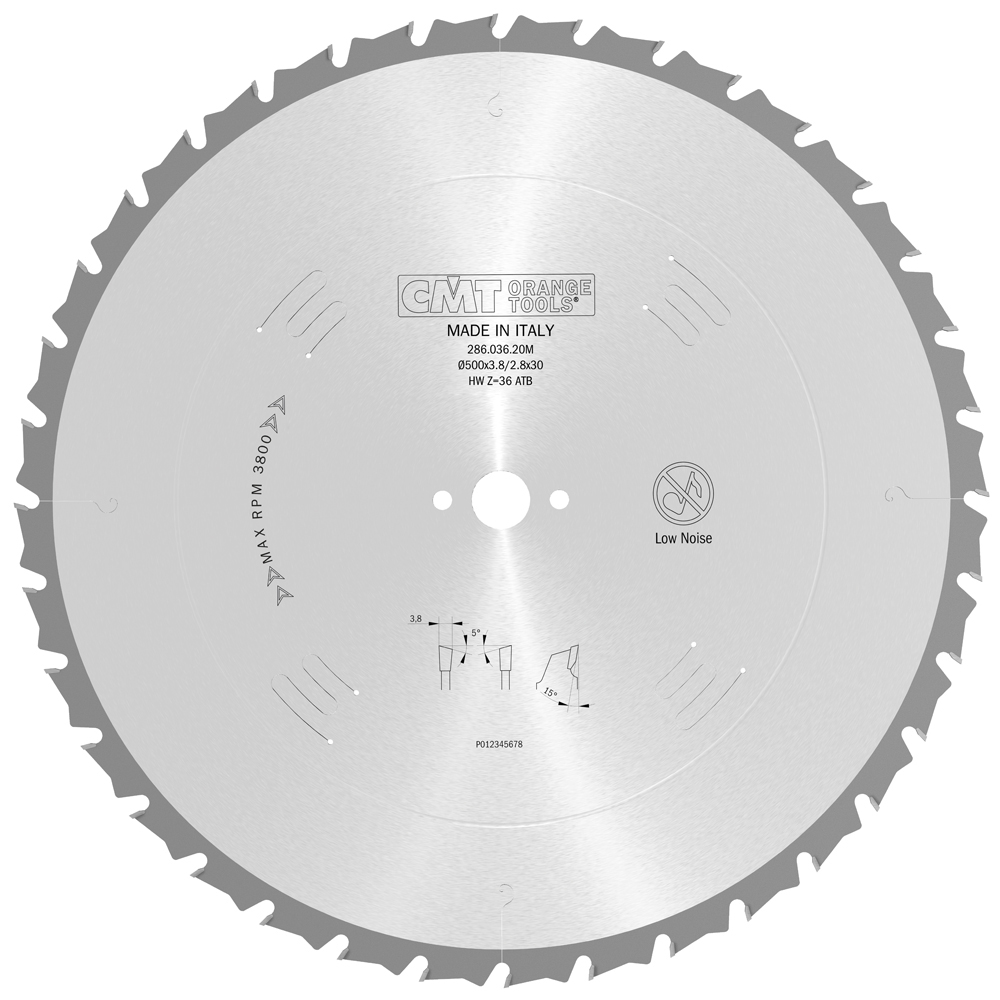

286.036.20M

|

500 | 30 | 2/10/60 | 36 | 3.8 | 2.8 | 15 | ATB 5 | |

|

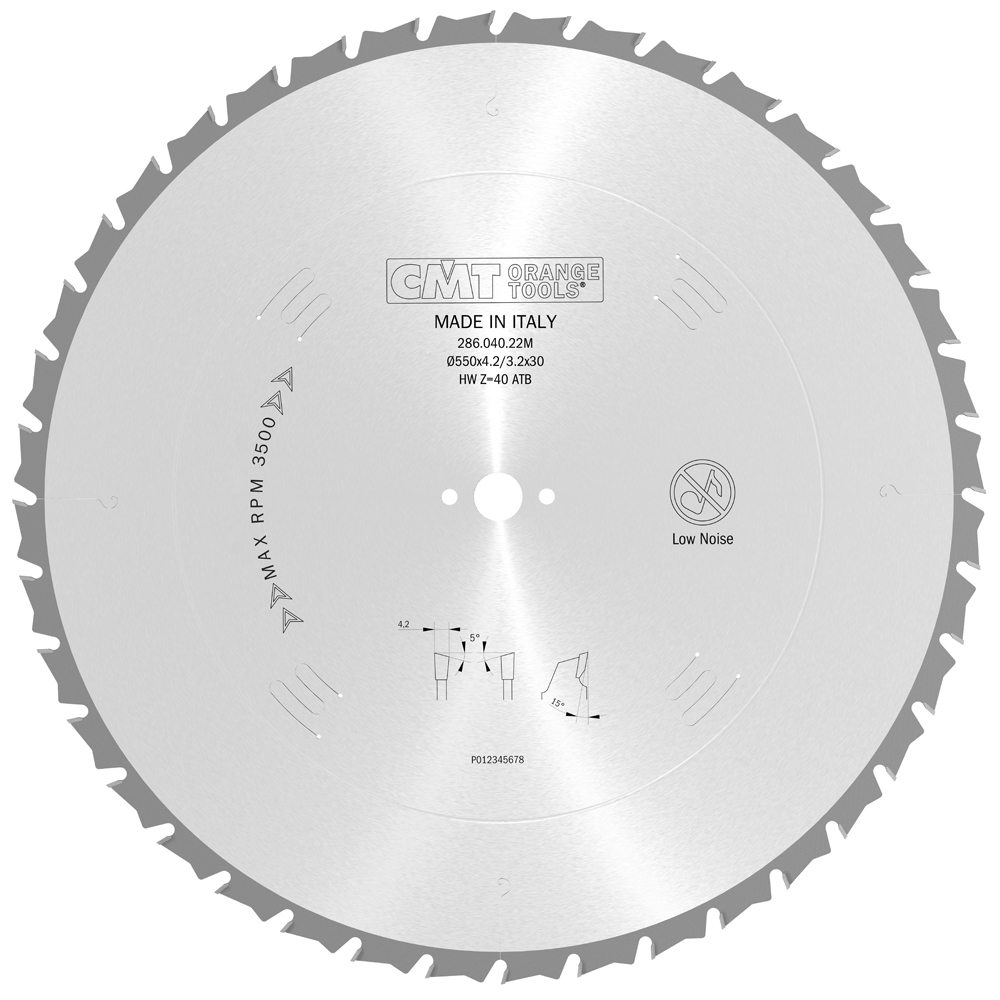

286.040.22M

|

550 | 30 | 2/10/60 | 40 | 4.2 | 3.2 | 15 | ATB 5 | |

|

286.040.24M

|

600 | 30 | 2/10/60 | 40 | 4.2 | 3.2 | 15 | ATB 5 | |

|

286.046.28M

|

* INDUSTRIAL LINE | 700 | 30 | 2/10/60 | 46 | 4.4 | 3.2 | 15 | ATB 5 |