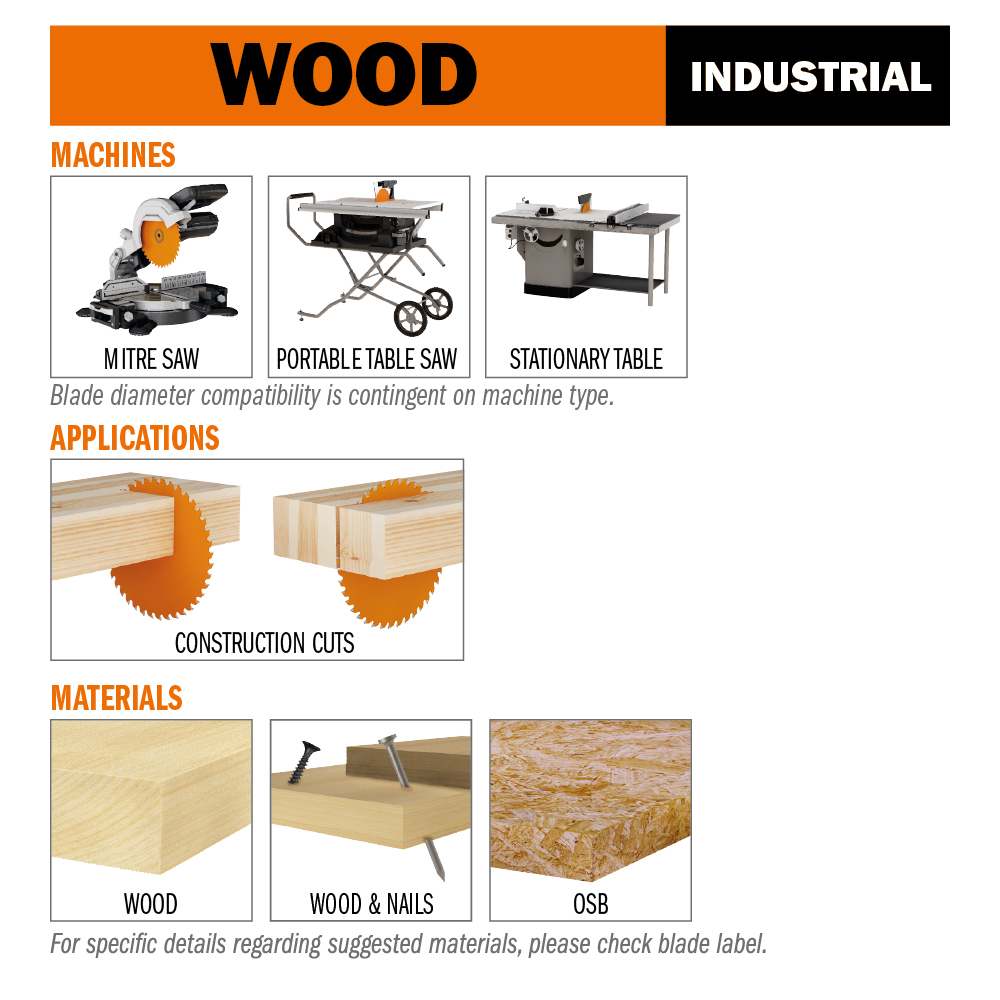

On-site Job Construction - INDUSTRIAL

286.INDUSTRIAL

|

|

LASER-CUT HIGH QUALITY STEEL PLATE BODY

Made with 44 HRC high quality steel and laser-cut to ensure longer life and precision cutting. |

|

|

LASER-CUT SOUND DAMPENING SLOTS

Slots reduce vibrations and noise by 10% compared to blades without it. This feature improves cut quality and extends blade life. In full compliance with National Noise Emission Standards and Regulations. |

|

|

TENSIONING RING (∅250mm and above)

A visible tensioning ring on blade body provides stability during the cut and perfect concentricity during rotation. For improved performance, tensioning is fine-tuned according to machine/application. |

|

|

SILVER BRAZING

Silver Alloy Brazing prevents carbide from breaking during the cooling process and allows teeth to withstand high stress and impact especially when cutting harder woods and composite materials. |

|

|

INDUSTRIAL SINTERHIP HI-DENSITY CARBIDE

The SINTERHIP sintering process (Hot Isostatic Pressing) uses high temperature (up to 3500°F) and high pressure (up to 1500 psi) to fully consolidate carbide thereby resulting in a porosity-free product ensuring longer cutting life over traditional carbide and less risk of breakages. |

|

PRECISION SHARPENING

Each tooth is precision ground on a multi-axis CNC machine creating perfect edge angles that provide extra-clean cutting performance and extended life. Featuring less than 0.35 μm Rmax in edge roughness. |

|

|

|

ORANGE SHIELD® NON-STICK PTFE COATING

- Protects against corrosion and rust. - Reduces resin and residue build-up. - Reduces overheating and blade drag. - Improves performance and cutting life. |

SHOP TIPS:

Use our reduction ring from 30 to 25mm order n. 299.225.00 (for saw blades Ø250-300-315).

Use our reduction ring from 30 to 25mm order n. 299.228.00 (for saw blades Ø350 and larger).

Variations

Filter

| Item Code | Description | D | B | PH | Z | K | P | α | β |

|---|---|---|---|---|---|---|---|---|---|

|

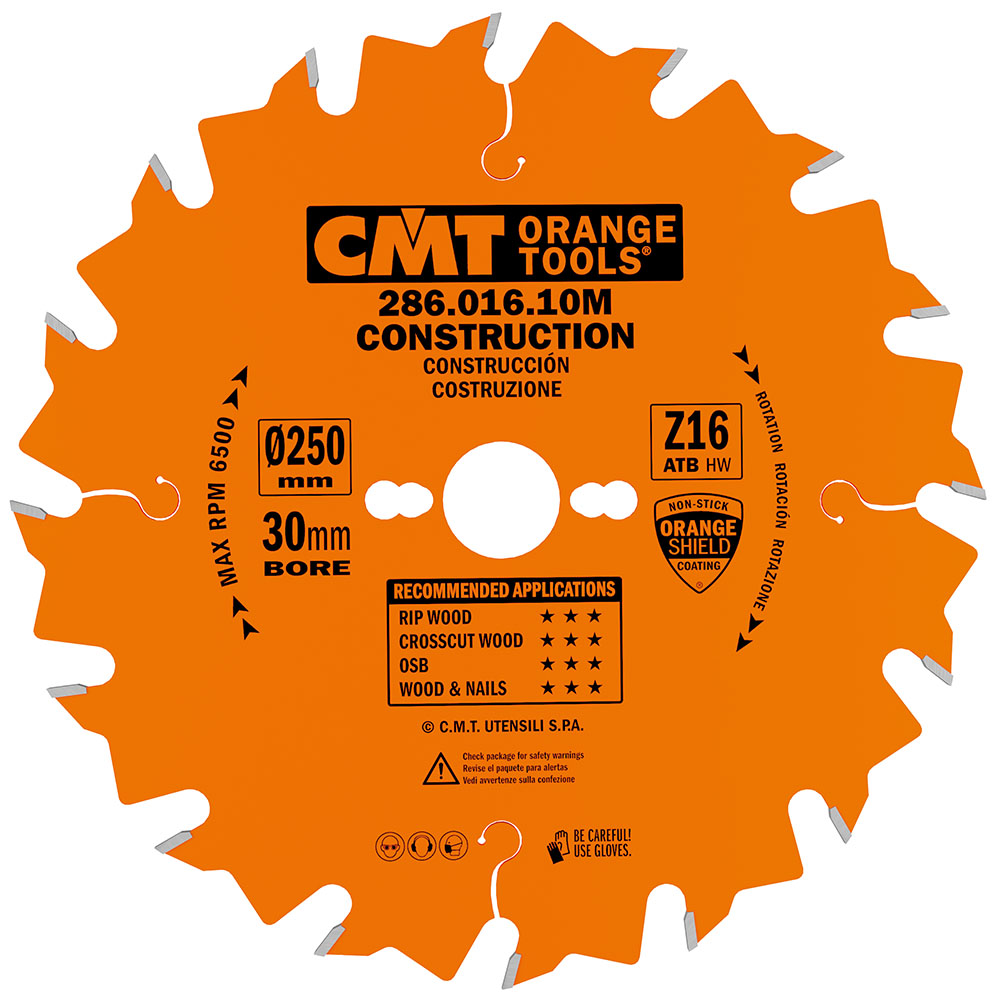

286.016.10M

|

NON-STICK ORANGE SHIELD COATING® | 250 | 30 | COMBI3 | 16 | 2.8 | 1.8 | 15 | ATB 5 |

|

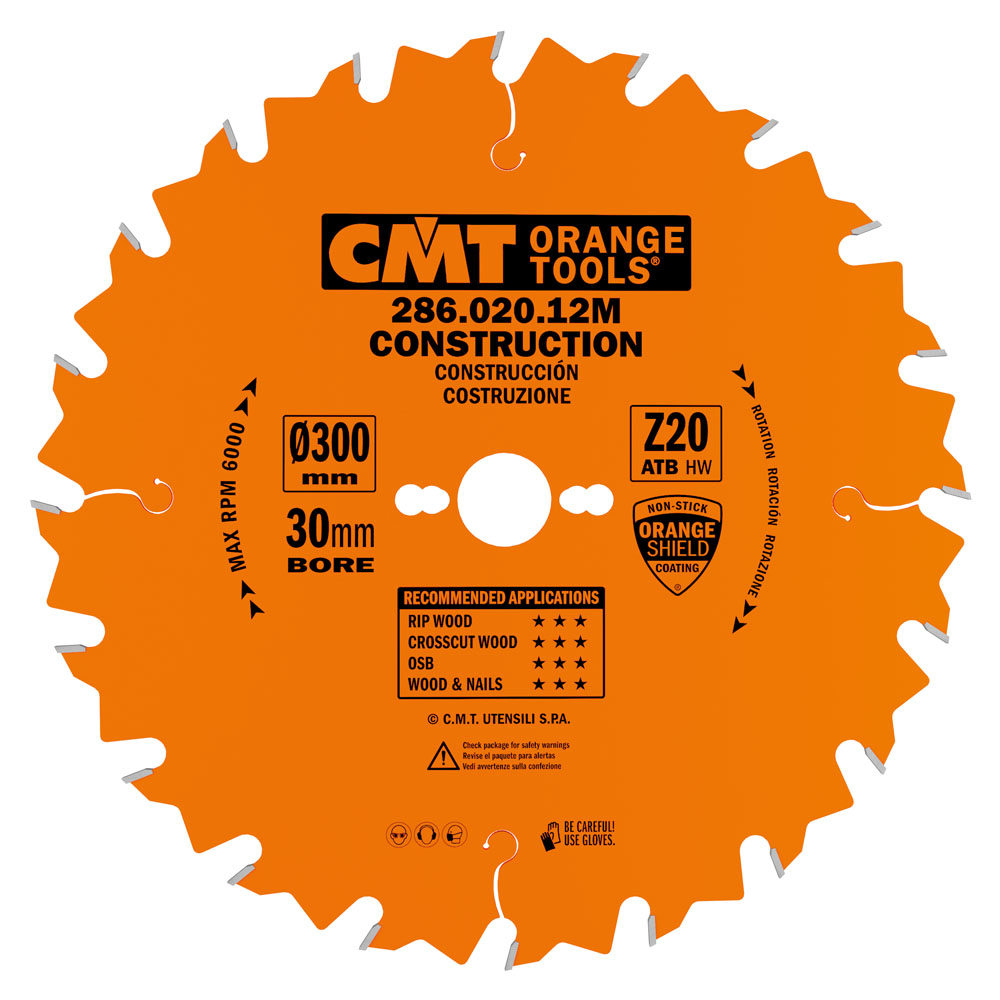

286.020.12M

|

NON-STICK ORANGE SHIELD COATING® | 300 | 30 | COMBI3 | 20 | 2.8 | 1.8 | 15 | ATB 5 |

|

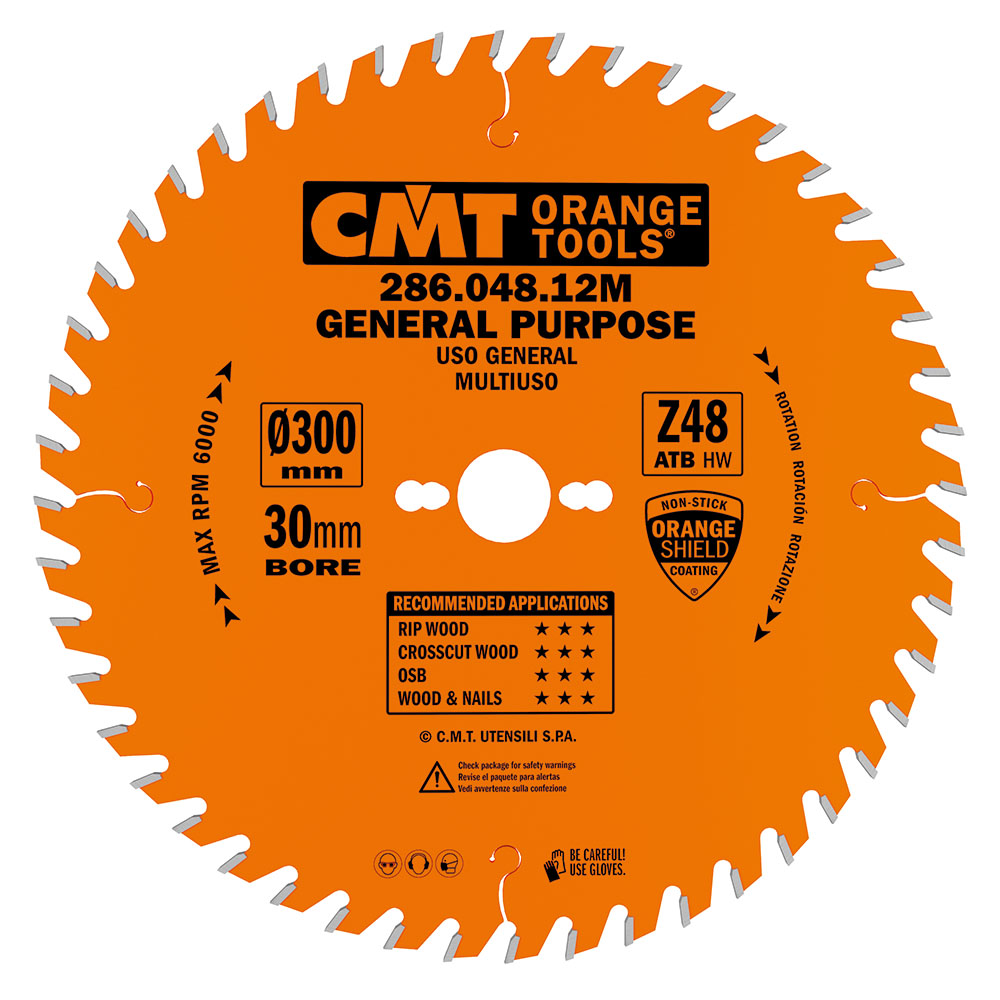

286.048.12M

|

Without limiter - NON-STICK ORANGE SHIELD COATING® | 300 | 30 | COMBI3 | 48 | 3.2 | 2.2 | 15 | ATB 10 |

|

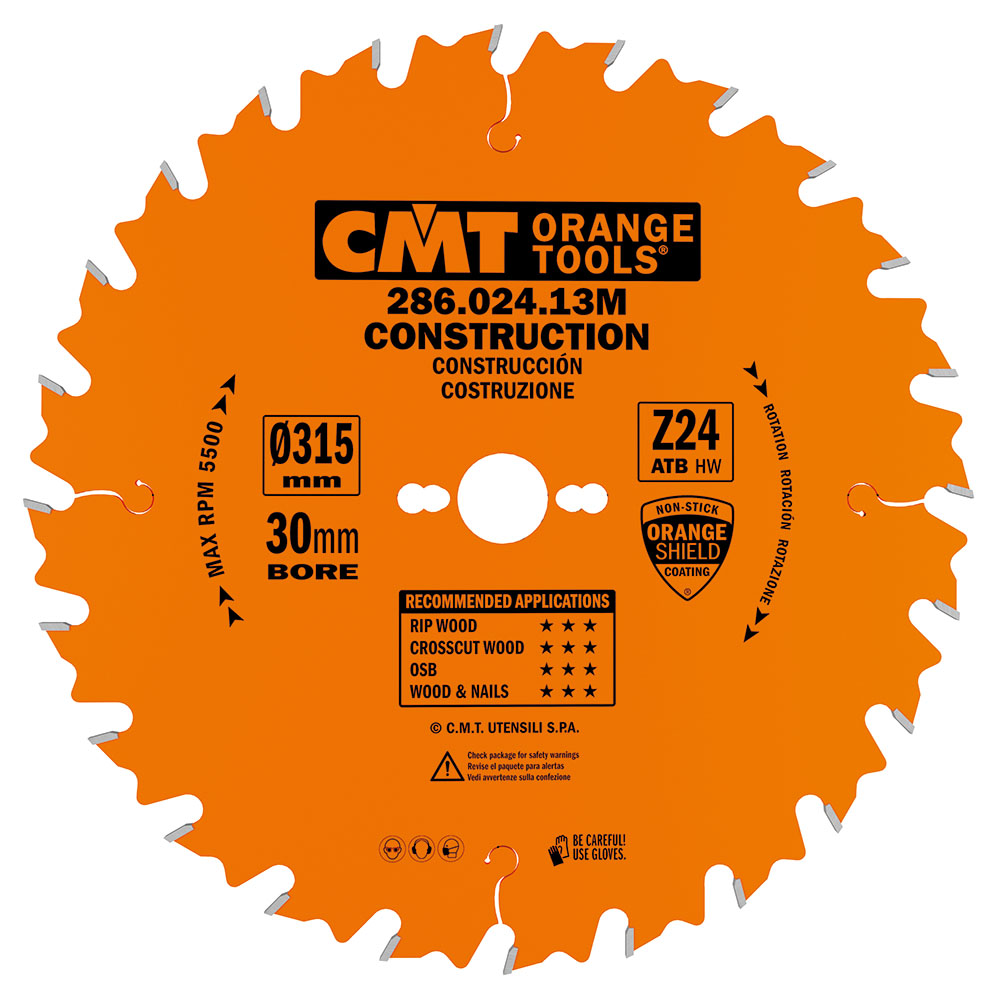

286.024.13M

|

315 | 30 | COMBI3 | 24 | 3.2 | 2.2 | 15 | ATB 5 | |

|

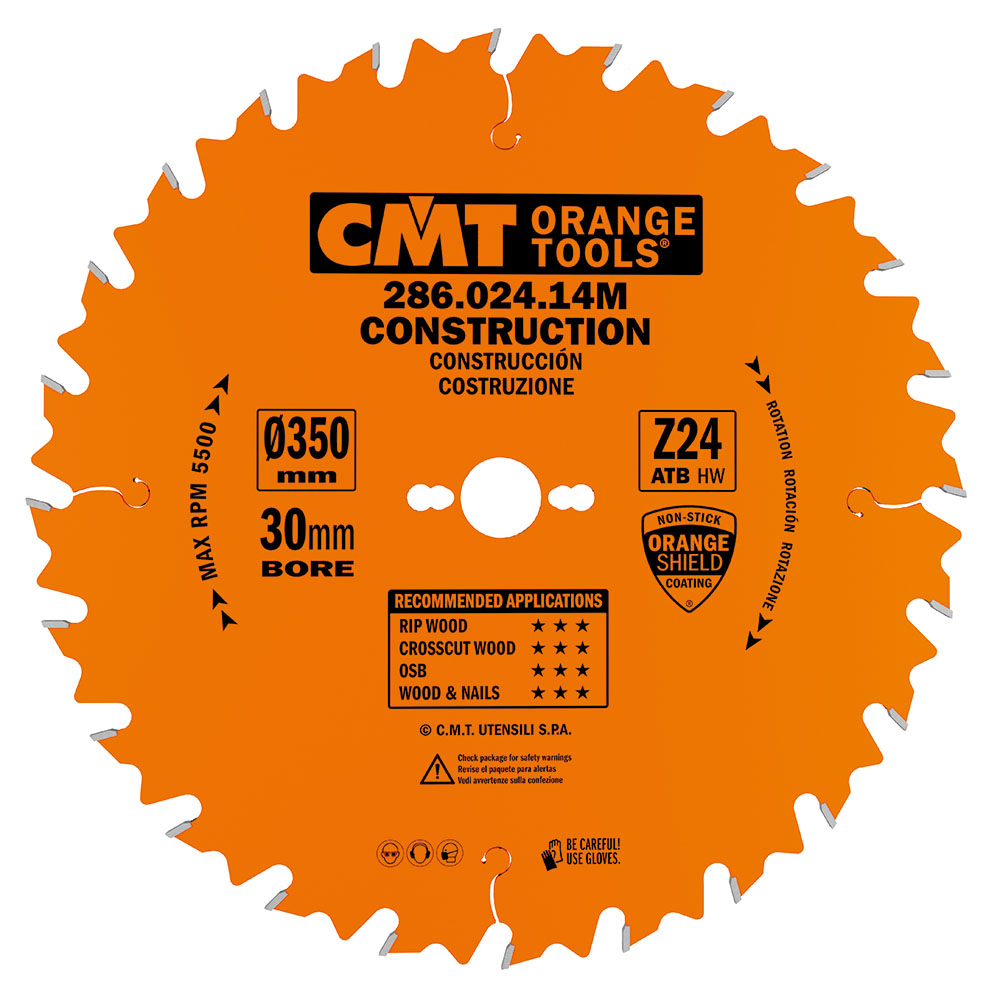

286.024.14M

|

NON-STICK ORANGE SHIELD COATING® | 350 | 30 | COMBI3 | 24 | 3.2 | 2.2 | 15 | ATB 5 |