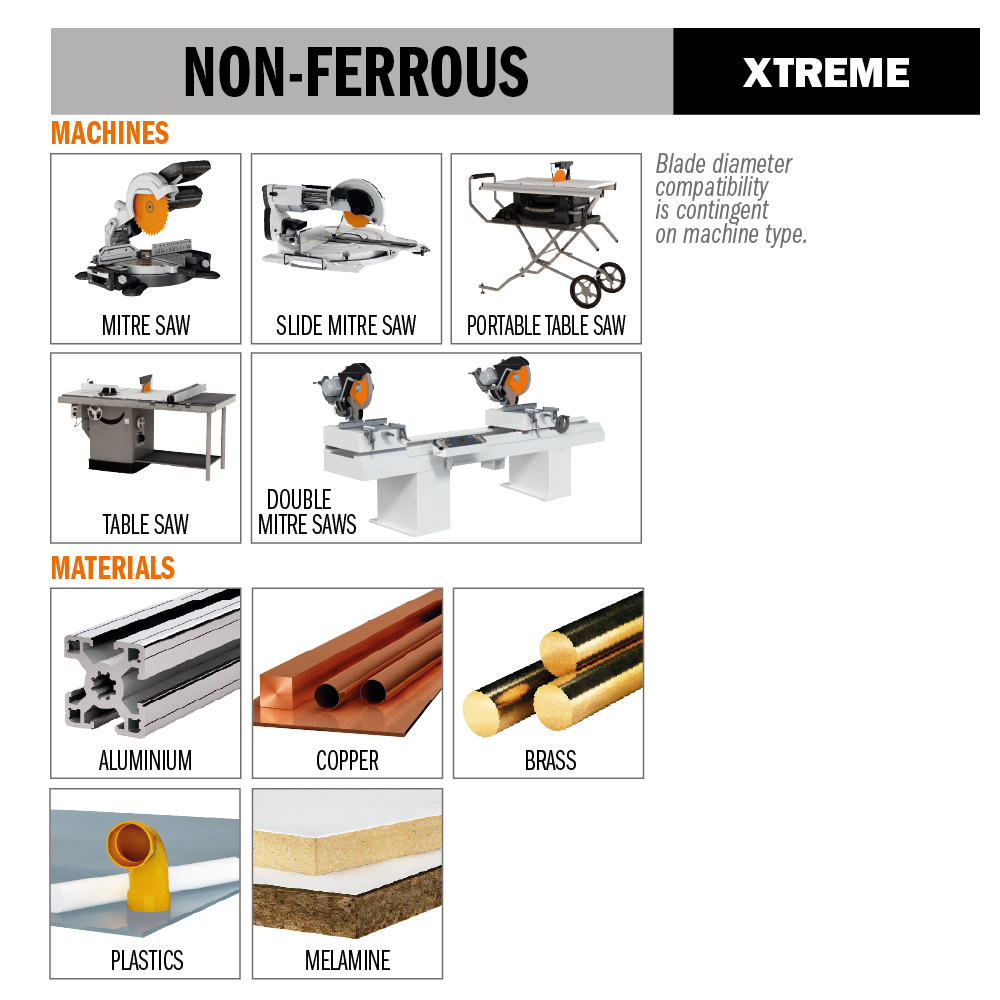

Non-ferrous metal and laminated panel circular saw blades

297-296

|

|

LASER-CUT PREMIUM QUALITY STEEL PLATE BODY |

|

|

LASER-CUT SOUND DAMPENING SLOTS |

|

|

TENSIONING RING (∅250mm and above) |

|

TRI-METAL BRAZING |

|

INDUSTRIAL CHROME CARBIDE |

|

PRECISION MIRROR FINISH SHARPENING |

|

|

HARD LAQUERING |

.png) |

CMT XTREME BALANCING* |

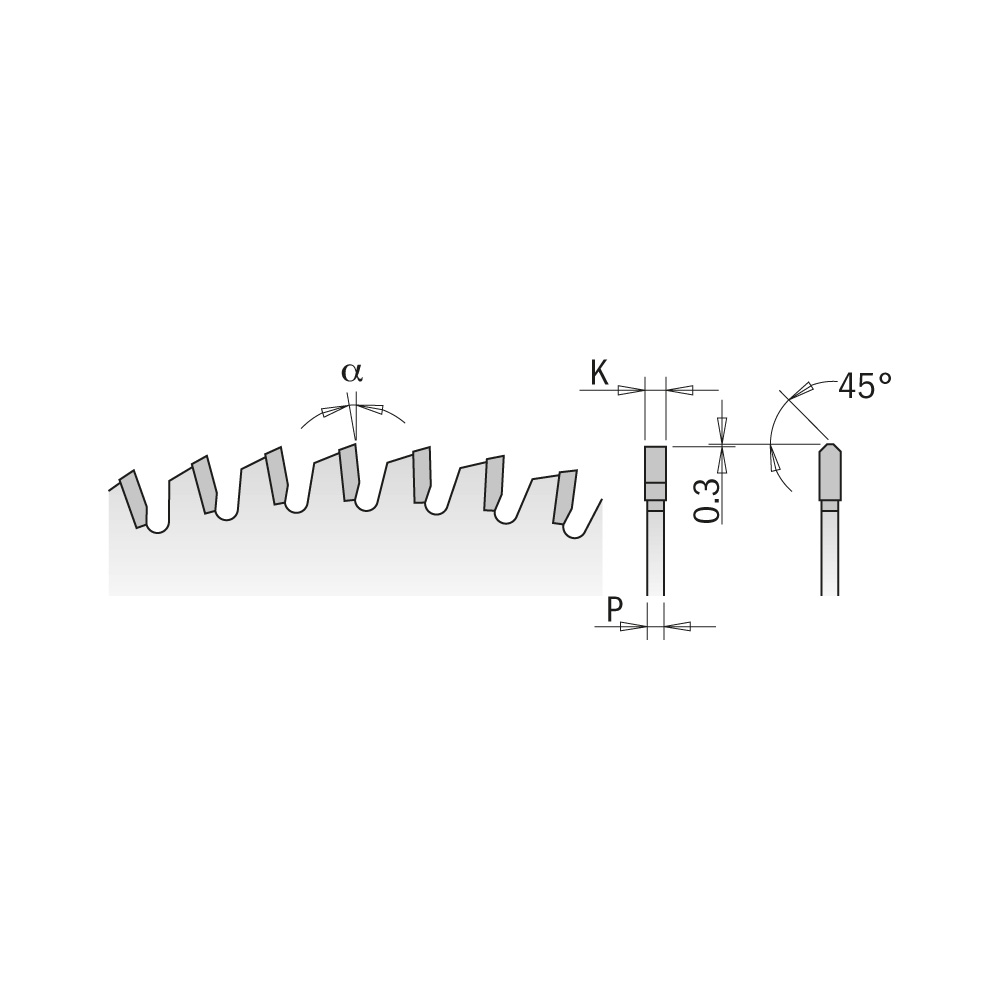

| Item Code | D | B | PH | Z | K | P | α | β |

|---|---|---|---|---|---|---|---|---|

|

297.080.10M

|

250 | 30 | COMBI3 | 80 | 3.2 | 2.5 | -6 | TCG |

|

297.080.10P

|

250 | 32 | 2/12/64 | 80 | 3.2 | 2.5 | -6 | TCG |

|

297.081.10M

|

254 | 30 | COMBI3 | 80 | 3.2 | 2.5 | -6 | TCG |

|

297.080.11M

|

260 | 30 | COMBI3 | 80 | 3.2 | 2.5 | -6 | TCG |

|

297.064.11M

|

280 | 30 | COMBI3 | 64 | 3.2 | 2.5 | -6 | TCG |

|

297.096.12M

|

300 | 30 | COMBI3 | 96 | 3.2 | 2.5 | -6 | TCG |

|

297.096.12P

|

300 | 32 | 2/12/64 | 96 | 3.2 | 2.5 | -6 | TCG |

|

297.096.13M

|

305 | 30 | COMBI3 | 96 | 3.2 | 2.5 | -6 | TCG |

|

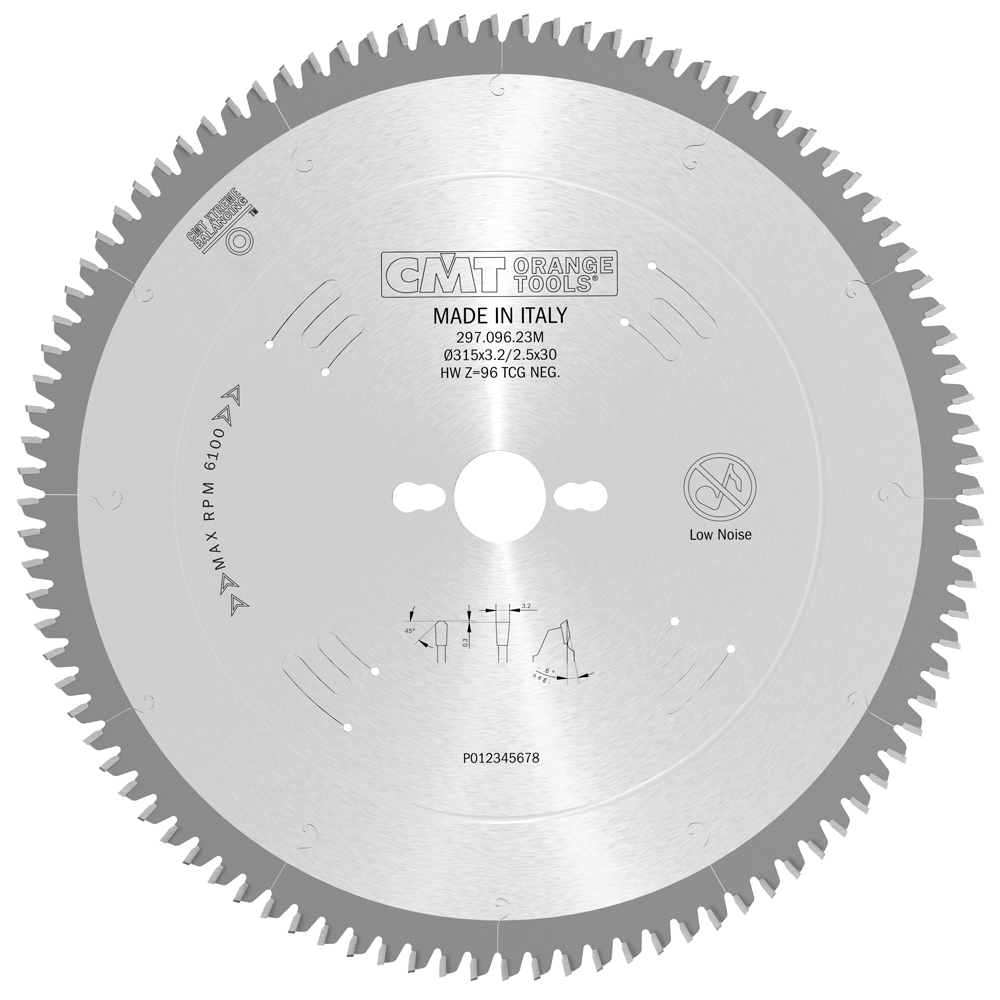

297.096.23M

|

315 | 30 | COMBI3 | 96 | 3.2 | 2.5 | -6 | TCG |

|

297.096.33M

|

330 | 30 | COMBI3 | 96 | 3.6 | 3 | -6 | TCG |

|

297.096.33P

|

330 | 32 | COMBI3 | 96 | 3.6 | 3 | -6 | TCG |

|

297.108.14M

|

350 | 30 | COMBI3 | 108 | 3.6 | 3 | -6 | TCG |

|

297.108.14P

|

350 | 32 | 4/12/64 | 108 | 3.6 | 3 | -6 | TCG |

|

297.108.16P

|

400 | 32 | 4/12/64 | 96 | 4 | 3.2 | -6 | TCG |

|

297.120.16M

|

400 | 30 | 2/10/60 | 120 | 4 | 3.2 | -6 | TCG |

|

297.120.16P

|

400 | 32 | 4/12/64 | 120 | 4.0 | 3.2 | -6 | TCG |

|

297.120.18P

|

450 | 32 | 4/12/64 | 120 | 4.2 | 3.5 | -6 | TCG |

|

Y297.140.18M

|

450 | 30 | 2/10/60 | 120 | 4.2 | 3.5 | -6 | TCG |

|

297.108.18P

|

450 | 32 | 2/12/64 | 96 | 4.2 | 3.5 | -6 | TCG |

|

297.120.20M

|

500 | 30 | 2/10/60 | 120 | 4.3 | 3.5 | -6 | TCG |

|

297.120.20P

|

500 | 32 | 2/12/64 | 120 | 4.3 | 3.5 | -6 | TCG |