Industrial non-ferrous metal and plastic circular saw blades

284

|

|

LASER-CUT PREMIUM QUALITY STEEL PLATE BODY |

|

|

LASER-CUT SOUND DAMPENING SLOTS |

|

|

TENSIONING RING (∅250mm and above) |

|

TRI-METAL BRAZING |

|

INDUSTRIAL CHROME CARBIDE |

|

PRECISION MIRROR FINISH SHARPENING |

|

|

HARD LAQUERING |

.png) |

CMT XTREME BALANCING* |

during cutting operations and to use a liquid lubricant.

Wax stick for lubrication NOT RECOMMENDED.

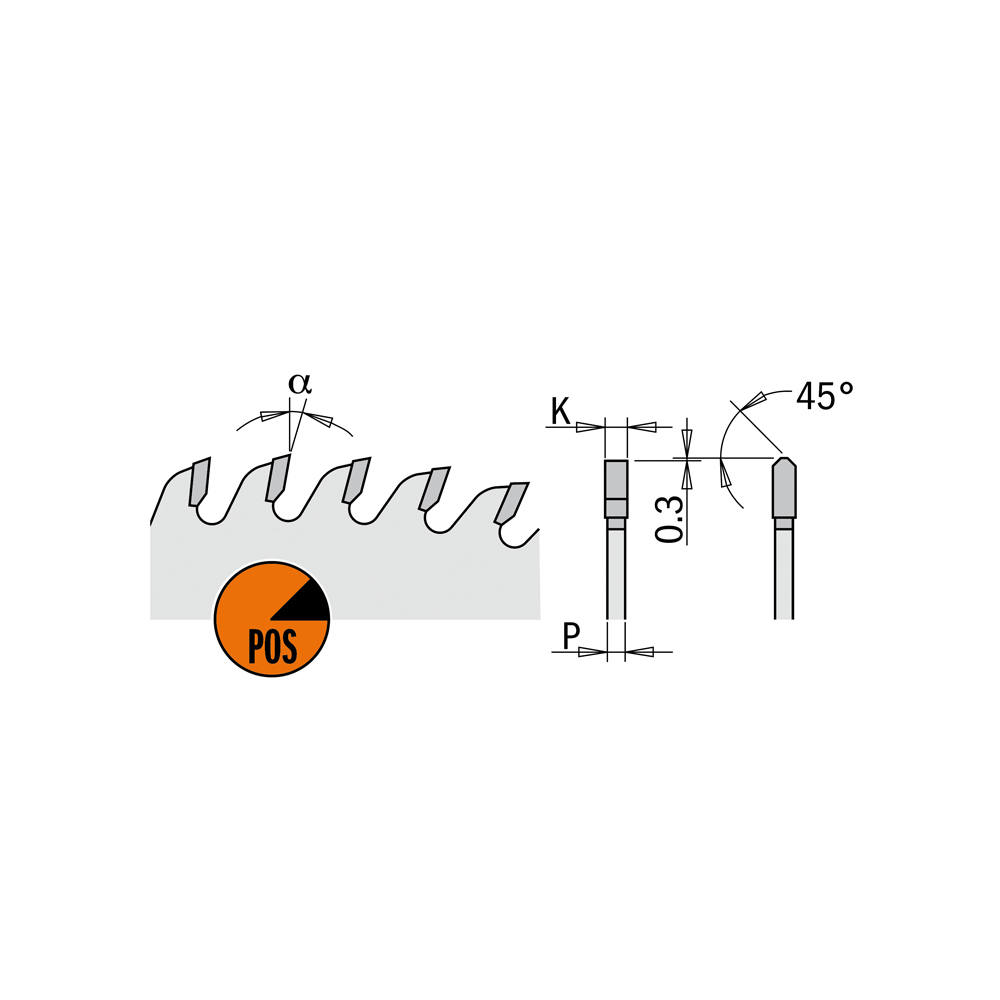

| Item Code | D | B | PH | Z | K | P | α |

|---|---|---|---|---|---|---|---|

|

284.080.10P

|

250 | 32 | 2/12/64 | 80 | 3.2 | 2.5 | 6 |

|

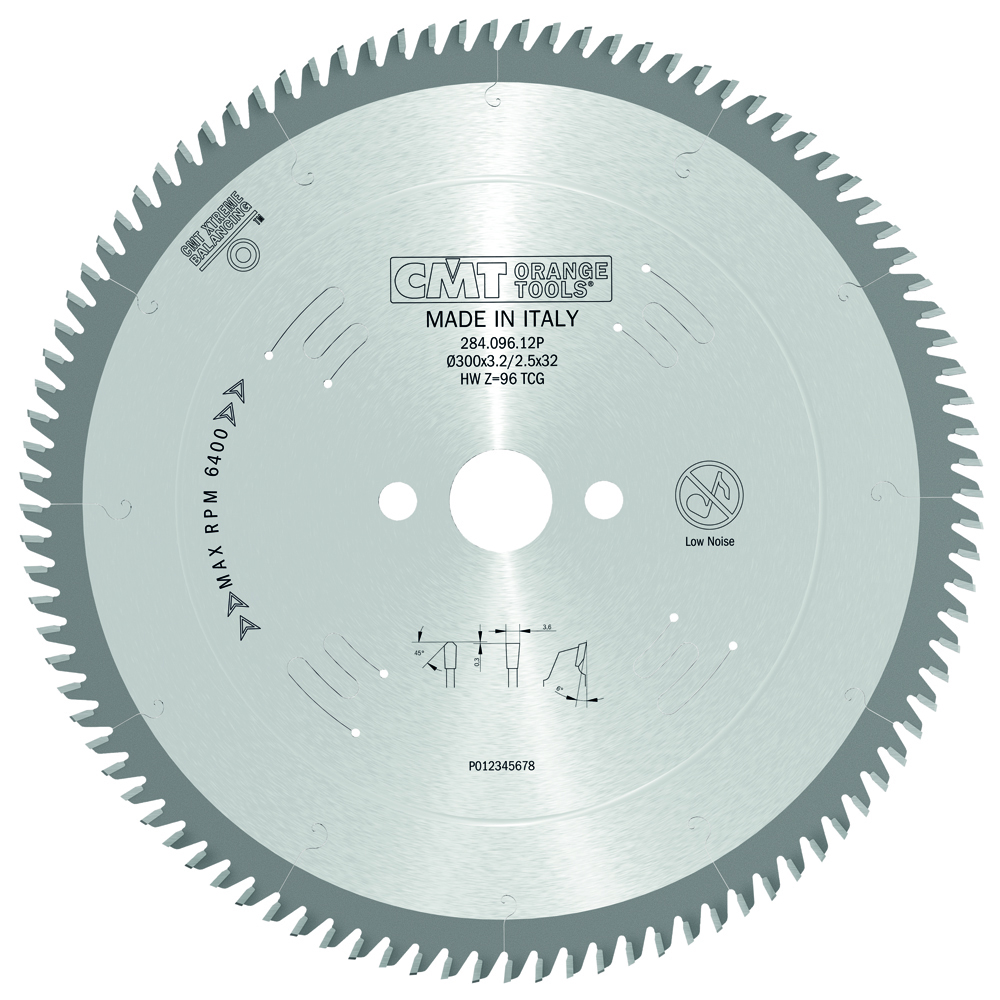

284.096.12P

|

300 | 32 | 2/12/64 | 96 | 3.2 | 2.5 | 6 |

|

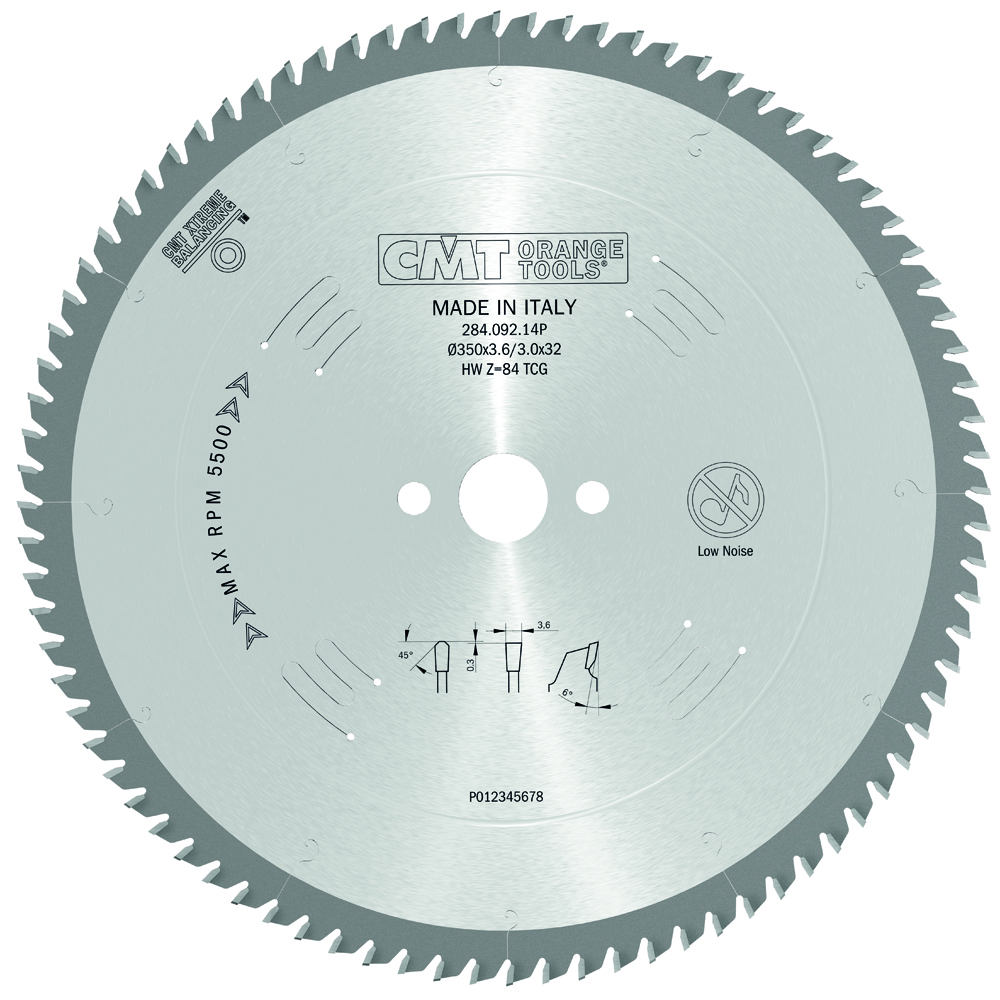

284.092.14P

|

350 | 32 | 2/12/64 | 84 | 3.6 | 3 | 6 |

|

284.108.14P

|

350 | 32 | 2/12/64 | 108 | 3.6 | 3 | 6 |

|

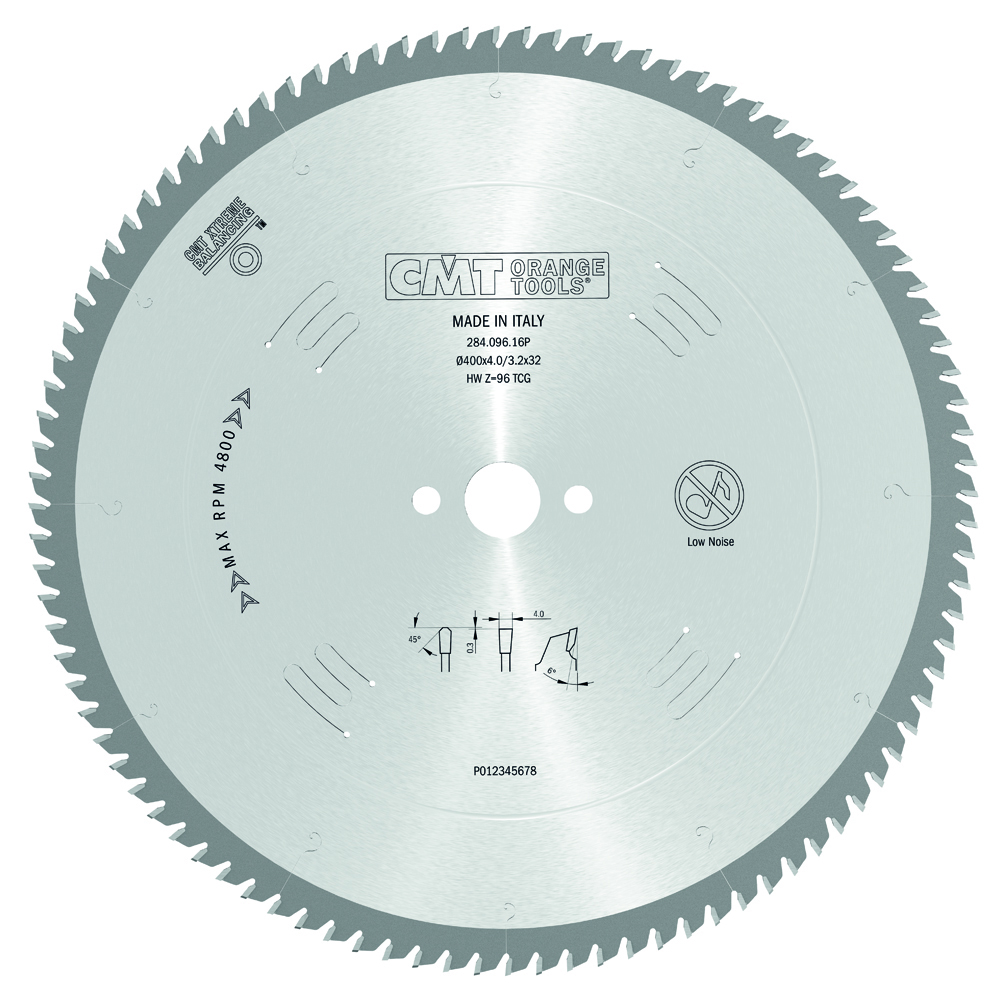

284.096.16P

|

400 | 32 | 2/12/64 | 96 | 4 | 3.2 | 6 |

|

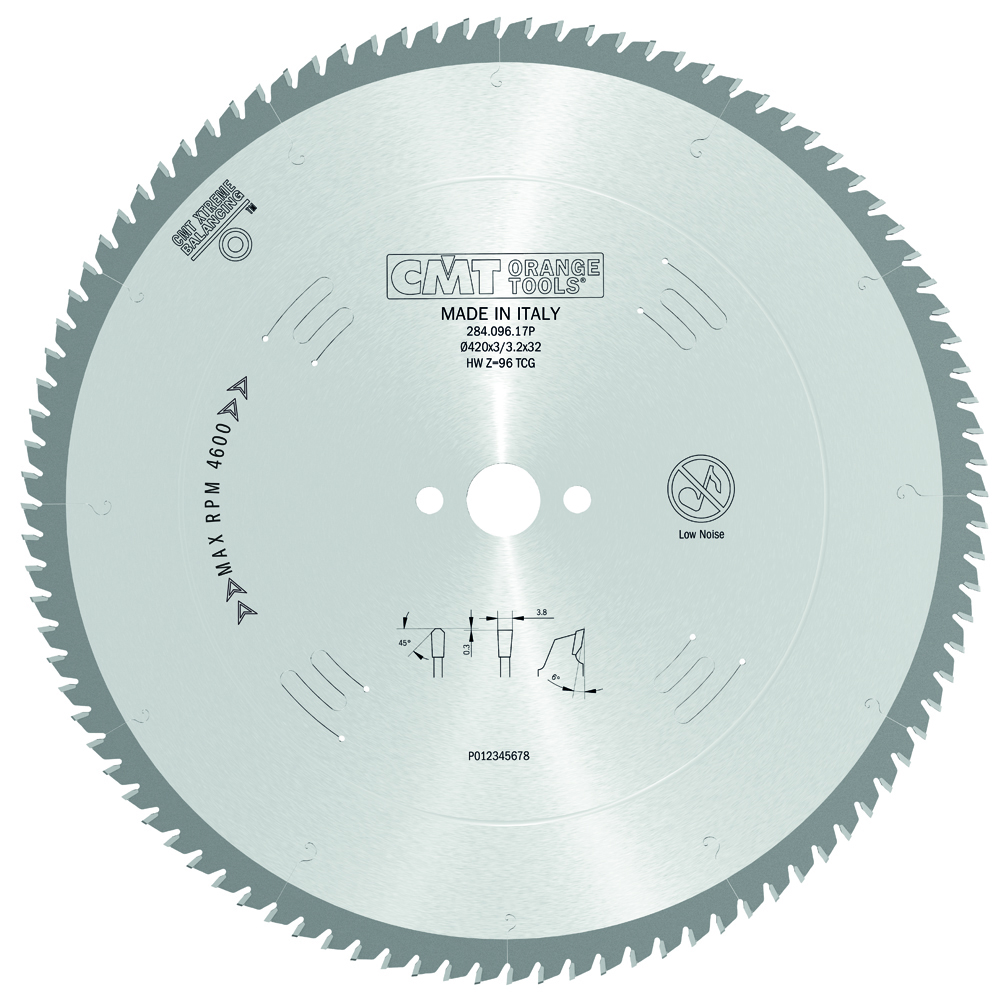

284.096.17P

|

420 | 32 | 2/12/64 | 96 | 3.8 | 3.2 | 6 |

|

284.108.18M

|

450 | 30 | 2/10/60 | 108 | 4.2 | 3.5 | 6 |

|

284.108.18P

|

450 | 32 | 2/12/64 | 108 | 4.2 | 3.5 | 6 |

|

284.120.20M

|

500 | 30 | 2/10/60 | 120 | 4.3 | 3.5 | 10 |

|

284.120.20P

|

500 | 32 | 2/12/64 | 120 | 4.3 | 3.5 | 10 |

|

284.132.22M

|

550 | 30 | 2/11/63 + 2/11/70 | 132 | 4.3 | 3.5 | 10 |

|

284.132.22P

|

550 | 32 | 2/11/63 + 2/11/70 | 132 | 4.3 | 3.5 | 10 |