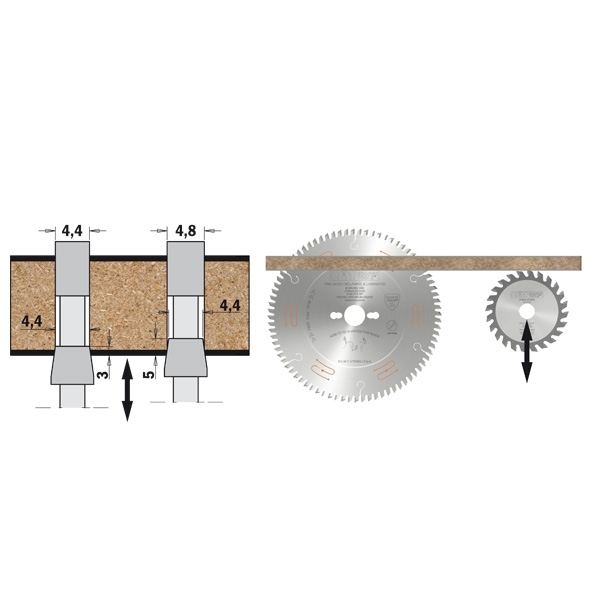

Conical Scoring Blades

288

|

|

LASER-CUT PREMIUM QUALITY STEEL PLATE BODY |

|

|

LASER-CUT SOUND DAMPENING SLOTS |

|

|

TENSIONING RING (∅250mm and above) |

|

TRI-METAL BRAZING |

|

INDUSTRIAL CHROME CARBIDE |

|

PRECISION MIRROR FINISH SHARPENING |

|

|

HARD LAQUERING |

.png) |

CMT XTREME BALANCING* |

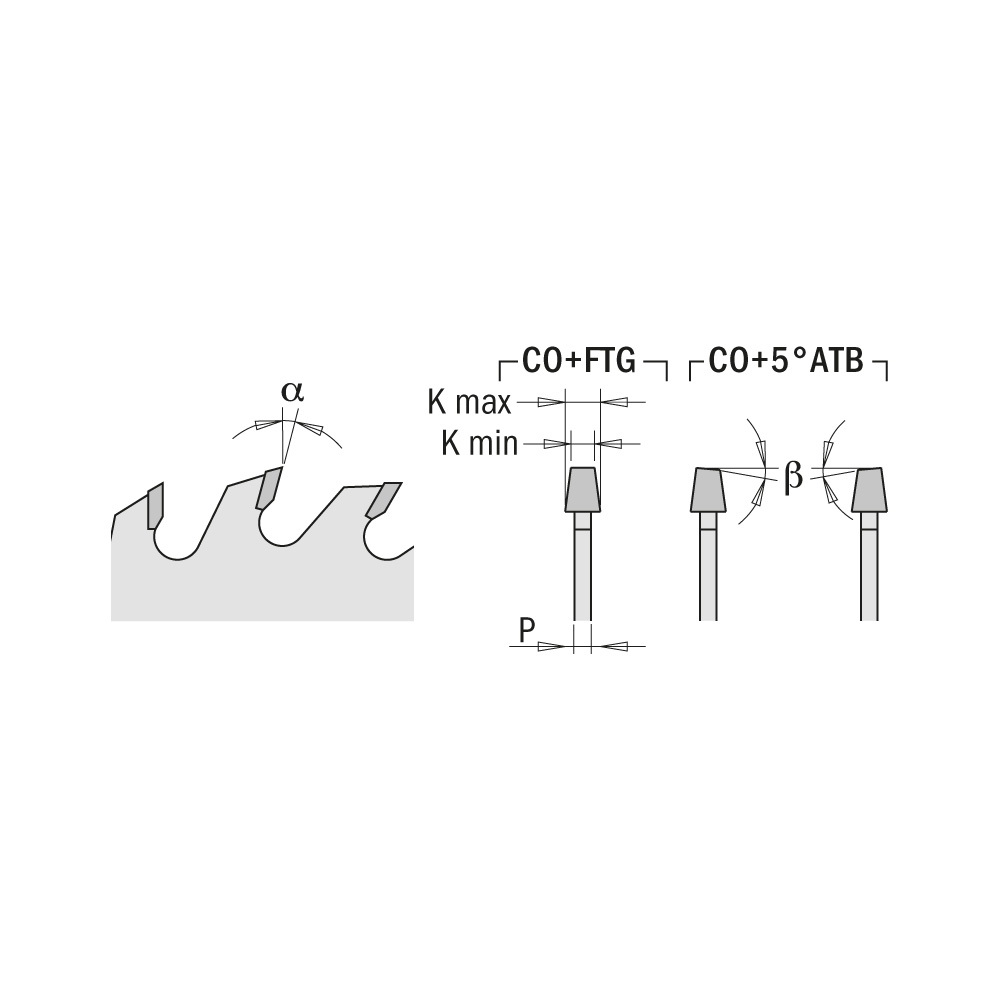

| Item Code | D | B | PH | Z | K | P | α | β |

|---|---|---|---|---|---|---|---|---|

|

S288.080.12H

|

80 | 20 | 12 | 3.1 - 4.0 | 2.2 | 10 | CO+FLAT | |

|

288.100.20H

|

100 | 20 | 20 | 3.1 - 4.0 | 2.5 | 5 | CO + ATB 5 | |

|

288.100.20K

|

100 | 22 | 20 | 3.1 - 4.0 | 2.5 | 5 | CO + ATB 5 | |

|

288.120.24H

|

120 | 20 | 24 | 3.1 - 4.0 | 2.5 | 5 | CO + ATB 5 | |

|

288.120.24H1

|

120 | 20 | 24 | 3.4 - 4.2 | 2.5 | 5 | CO + ATB 5 | |

|

288.120.24K

|

120 | 22 | 24 | 3.1 - 4.0 | 2.5 | 5 | CO + ATB 5 | |

|

288.121.24H

|

120 | 20 | 24 | 2.8 - 4.0 | 2.5 | 5 | CO + ATB 5 | |

|

288.125.24H

|

125 | 20 | 24 | 3.1 - 4.0 | 2.5 | 5 | CO + ATB 5 | |

|

288.125.24H1

|

125 | 20 | 24 | 3.4 - 4.2 | 2.5 | 5 | CO + ATB 5 | |

|

288.125.24H2

|

125 | 20 | 24 | 4.3 - 5.5 | 3.2 | 10 | CO + FLAT | |

|

288.125.24K

|

125 | 22 | 24 | 3.1 - 4.0 | 2.5 | 5 | CO + ATB 5 | |

|

288.125.24Q

|

125 | 45 | 24 | 4.3 - 5.5 | 3.2 | 10 | CO + FLAT | |

|

288.150.36Q

|

150 | 45 | 3/11/70 | 36 | 4.3 - 5.5 | 3.2 | 10 | CO + FLAT |

|

288.160.36O

|

160 | 55 | 3/7/66 + 3/6/84 | 36 | 4.3 - 5.5 | 3.2 | 10 | CO + FLAT |

|

288.160.36Q

|

160 | 45 | 3/11/70 | 36 | 4.3 - 5.5 | 3.2 | 10 | CO + FLAT |

|

288.180.36M

|

180 | 30 | COMBI3 | 36 | 4.45 - 5.3 | 3.2 | 10 | CO + FLAT |

|

288.180.36Q

|

180 | 45 | 36 | 4.7 - 6.0 | 3.5 | 10 | CO + FTG | |

|

288.180.36Q2

|

180 | 45 | 36 | 4.3 - 5.5 | 3.2 | 8 | CO + ATB 5 | |

|

288.180.44T

|

180 | 50 | 3/12.5/80 | 44 | 4.3 - 5.5 | 3.2 | 10 | CO + FTG |

|

288.200.36H

|

200 | 20 | 36 | 4.4 - 5.3 | 3.2 | 10 | CO + FTG | |

|

288.200.36J

|

200 | 65 | 2/9/100 + 2/9/110 | 36 | 4.45 - 5.3 | 3.2 | 10 | CO + FTG |

|

288.200.36Q

|

200 | 45 | 36 | 4.7 - 6.0 | 3.5 | 10 | CO + FTG | |

|

Y288.200.36Q2

|

200 | 45 | 36 | 4.3 - 5.5 | 3.2 | 10 | CO+FTG | |

|

288.215.42T

|

215 | 50 | 3/15/80 | 42 | 4.3 - 5.5 | 3.2 | 8 | CO + FTG |

|

288.300.48T

|

300 | 50 | 3/15/80 | 48 | 4.3 - 5.5 | 3.2 | 10 | CO + FTG |

|

288.300.72J

|

300 | 65 | 2/9/100 + 2/9/110 | 72 | 4.3 - 5.5 | 3.2 | 10 | CO + FTG |