|

|

LASER-CUT PREMIUM QUALITY STEEL PLATE BODY

Made with 46-48 HRC premium quality harmonic steel from Germany

and laser-cut to perfection providing tighter tolerances translating

to longer life and accurate cutting ability.

|

|

|

LASER-CUT SOUND DAMPENING SLOTS

Slots reduce vibrations and noise by 10% compared to blades without it.

This feature improves cut quality and extends blade life.

In full compliance with National Noise Emission Standards and Regulations.

|

|

|

TENSIONING RING (∅250mm and above)

A visible tensioning ring on blade body provides stability during the cut

and perfect concentricity during rotation. For improved performance,

tensioning is fine-tuned according to machine/application.

|

|

|

TRI-METAL BRAZING

Silver-Copper-Silver Tri-Metal Brazing prevents carbide from breaking

during the cooling process and allows teeth to withstand high stress

and impact especially when cutting harder woods and composite materials.

|

|

|

INDUSTRIAL CHROME CARBIDE

Cutting teeth are made from a specially formulated chrome carbide

which stays sharper longer by reducing cutting edge abrasion,

improving cut quality and tool life.

|

|

|

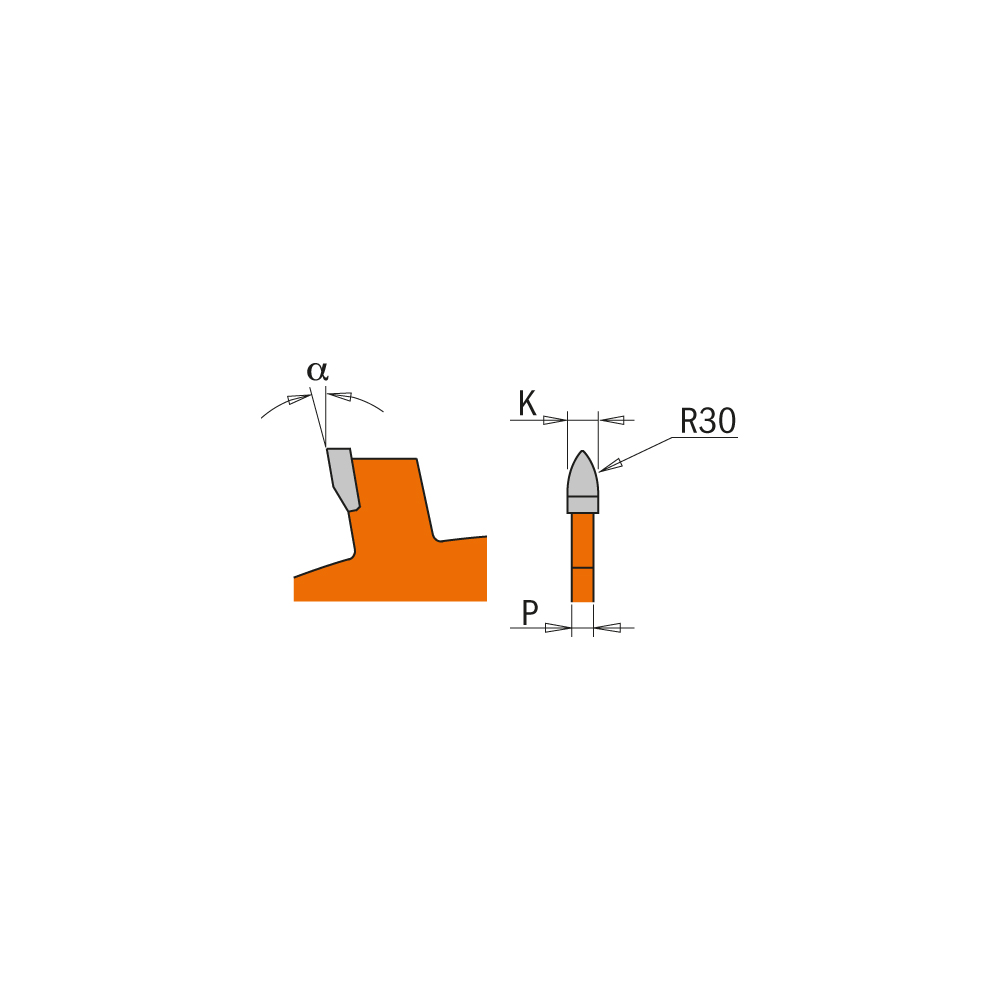

PRECISION MIRROR FINISH SHARPENING

Each tooth is precision ground on a multi-axis CNC machine creating

perfect edge angles that provide extra-clean cutting performance

and extended life. Featuring less than 0.25 µm Rmax in edge roughness.

|

|

|

HARD LAQUERING

Protects against corrosion and rust.

|

|

|

CMT XTREME BALANCING*

This system allows for extremely accurate dynamic balancing of the blade,

several orders of magnitude above and beyond that

which is currently available in the marketplace.

*TRADEMARK & INT. PAT. PEND.

|

®Any brand names mentioned in CMT product catalogues and on the CMT website are the property of their respective owners.

.png)