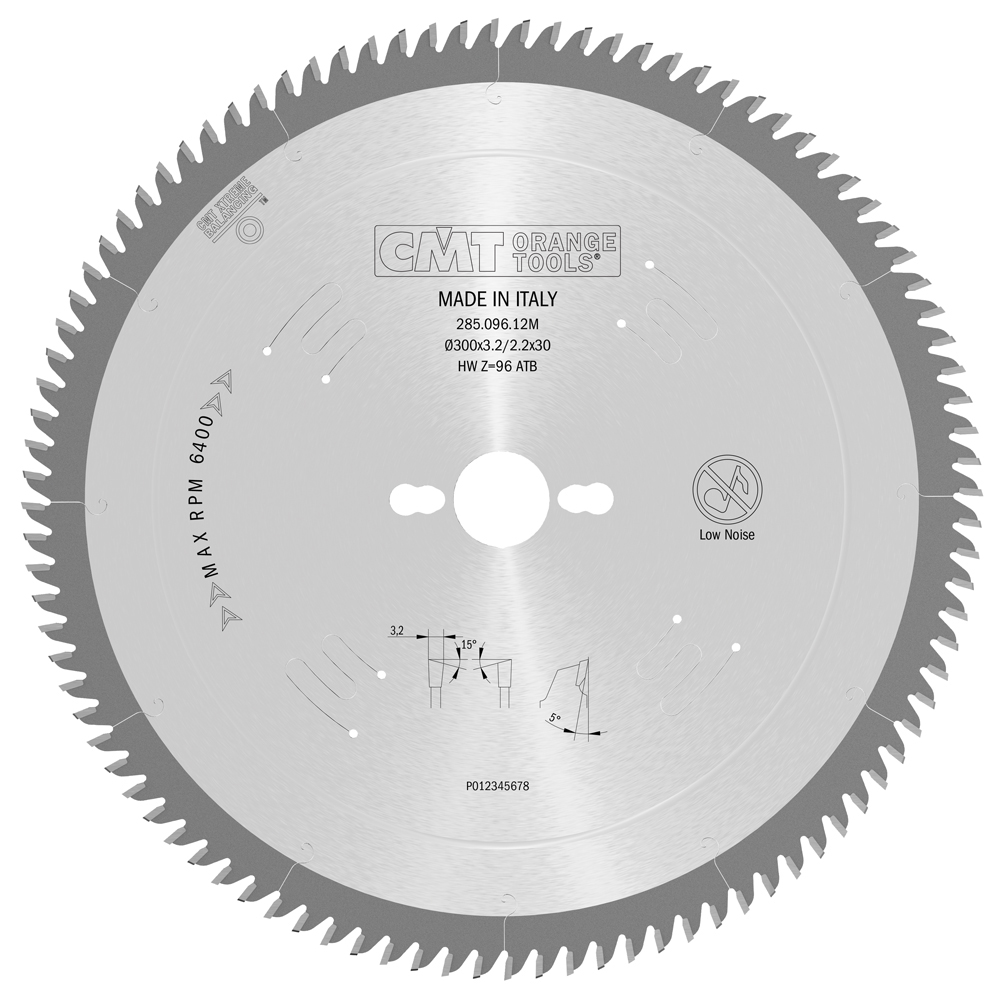

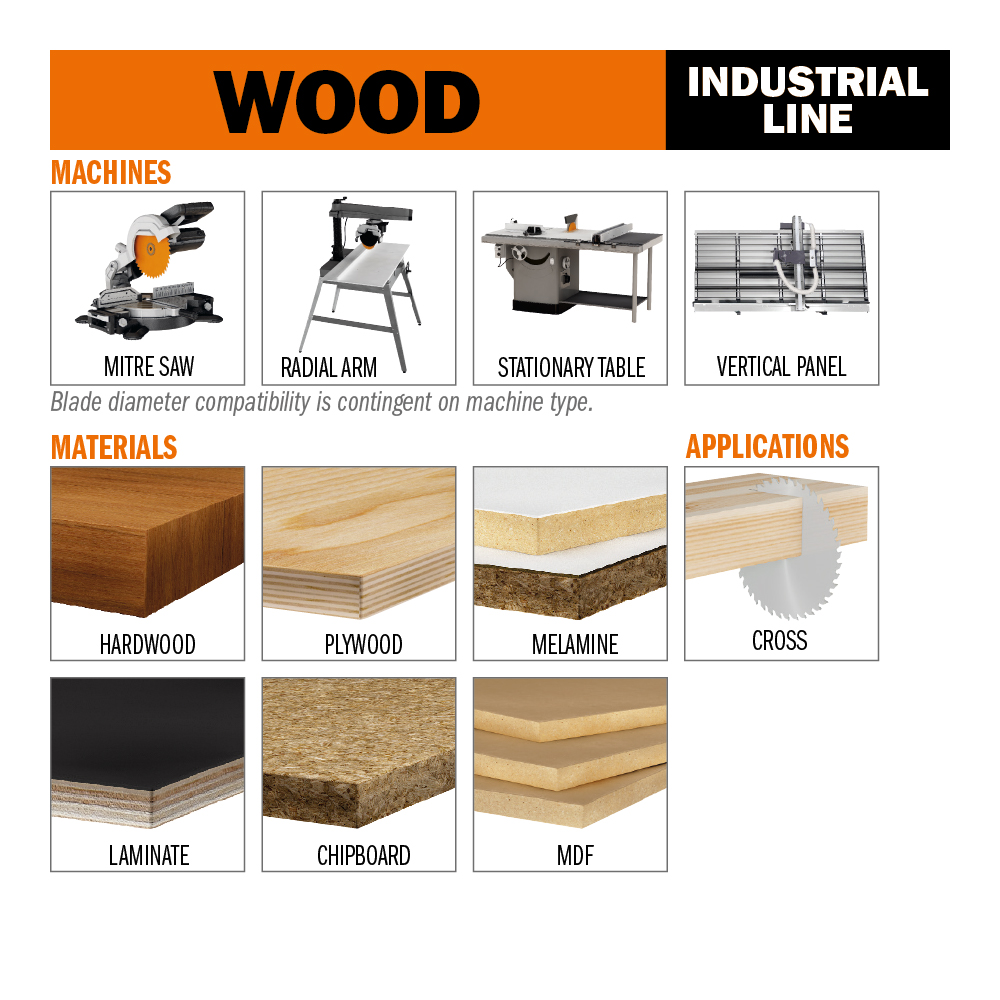

Fine finishing circular saw blades

285.FF

|

|

LASER-CUT PREMIUM QUALITY STEEL PLATE BODY |

|

|

LASER-CUT SOUND DAMPENING SLOTS |

|

|

TENSIONING RING (∅250mm and above) |

|

TRI-METAL BRAZING |

|

INDUSTRIAL CHROME CARBIDE |

|

PRECISION MIRROR FINISH SHARPENING |

|

|

HARD LAQUERING |

.png) |

CMT XTREME BALANCING* |

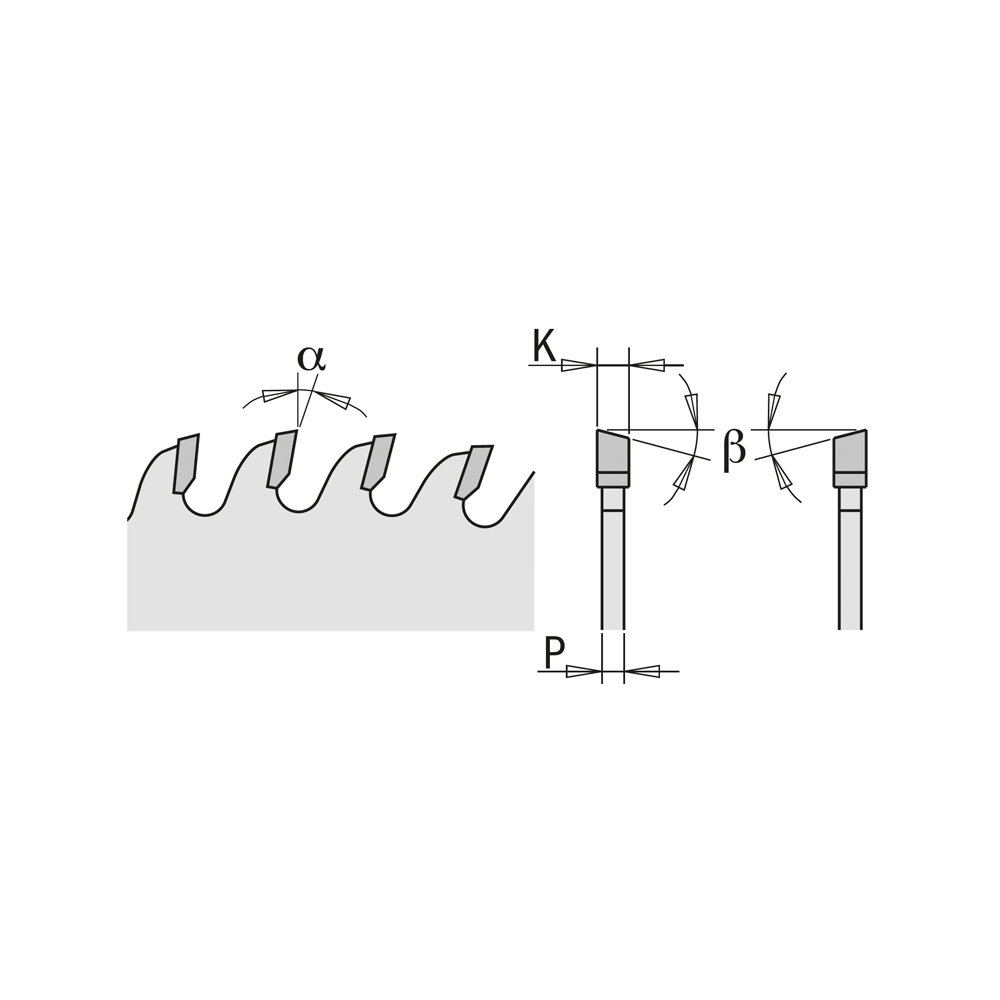

| Item Code | D | Z | B | PH | β | K | P | α |

|---|---|---|---|---|---|---|---|---|

|

285.080.10M

|

250 | 80 | 30 | COMBI3 | ATB 15 | 3.2 | 2.2 | 5 |

|

285.080.10R

|

250 | 80 | 35 | ATB 15 | 3.2 | 2.2 | 5 | |

|

285.096.12M

|

300 | 96 | 30 | COMBI3 | ATB 15 | 3.2 | 2.2 | 5 |

|

285.096.12R

|

300 | 96 | 35 | COMBI3 | ATB 15 | 3.2 | 2.2 | 5 |

|

285.108.14M

|

350 | 108 | 30 | COMBI3 | ATB 15 | 3.5 | 2.5 | 5 |

|

285.108.14R

|

350 | 108 | 35 | ATB 15 | 3.5 | 2.5 | 5 | |

|

285.120.16M

|

400 | 120 | 30 | COMBI3 | ATB 15 | 3.5 | 2.5 | 10 |