Industrial chrome coated circular saw blades

285.chromefinish

|

|

LASER-CUT PREMIUM QUALITY STEEL PLATE BODY

Made with 46-48 HRC premium quality harmonic steel from Germany and laser-cut to perfection providing tighter tolerances translating to longer life and accurate cutting ability. |

|

LASER-CUT SOUND DAMPENING SLOTS POLYMER-FILLED

Slots filled with sound-dampening polymer reduce vibrations and noise by 25% compared to blades without it.* *This feature improves cut quality and extends blade life. *In full compliance with National Noise Emission Standards and Regulations. |

|

|

TENSIONING RING (∅250mm and above)

A visible tensioning ring on blade body provides stability during the cut and perfect concentricity during rotation.

For improved performance, tensioning is fine-tuned according to machine/application.

|

|

TRI-METAL BRAZING

Silver-Copper-Silver Tri-Metal Brazing prevents carbide from breaking during the cooling

process and allows teeth to withstand high stress

and impact especially when cutting harder woods and composite materials. |

|

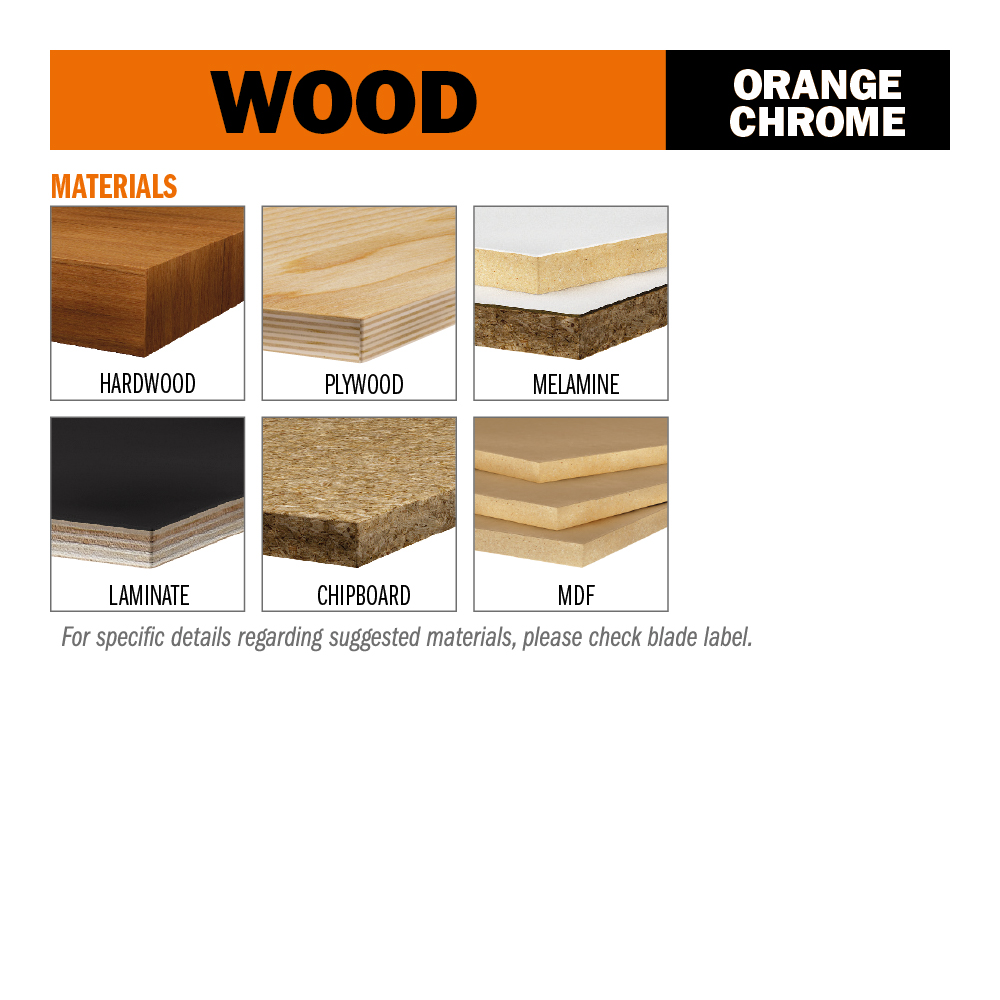

INDUSTRIAL CHROME CARBIDE

Cutting teeth are made from a specially formulated chrome carbide which stays sharper longer by reducing cutting edge abrasion, improving cut quality and tool life. |

|

PRECISION MIRROR FINISH SHARPENING

Each tooth is precision ground on a multi-axis CNC machine creating perfect edge angles

that provide extra-clean cutting performance and extended life.

Featuring less than 0.25 µm Rmax in edge roughness.

|

|

ORANGE CHROME® COATING

• Protects the tool against corrosion, rust and accumulation of resin and residues. • Guarantees longer tool life. • Lower power absorption by motor. • Smoother blade movement throughout cutting operation. • Tool maintenance is fast and easy. |

.png) |

CMT XTREME BALANCING*

This system allows for extremely accurate dynamic balancing of the blade, several orders of magnitude above and beyond that which is currently available in the marketplace. *TRADEMARK & INT. PAT. PEND. |

Variations

Filter

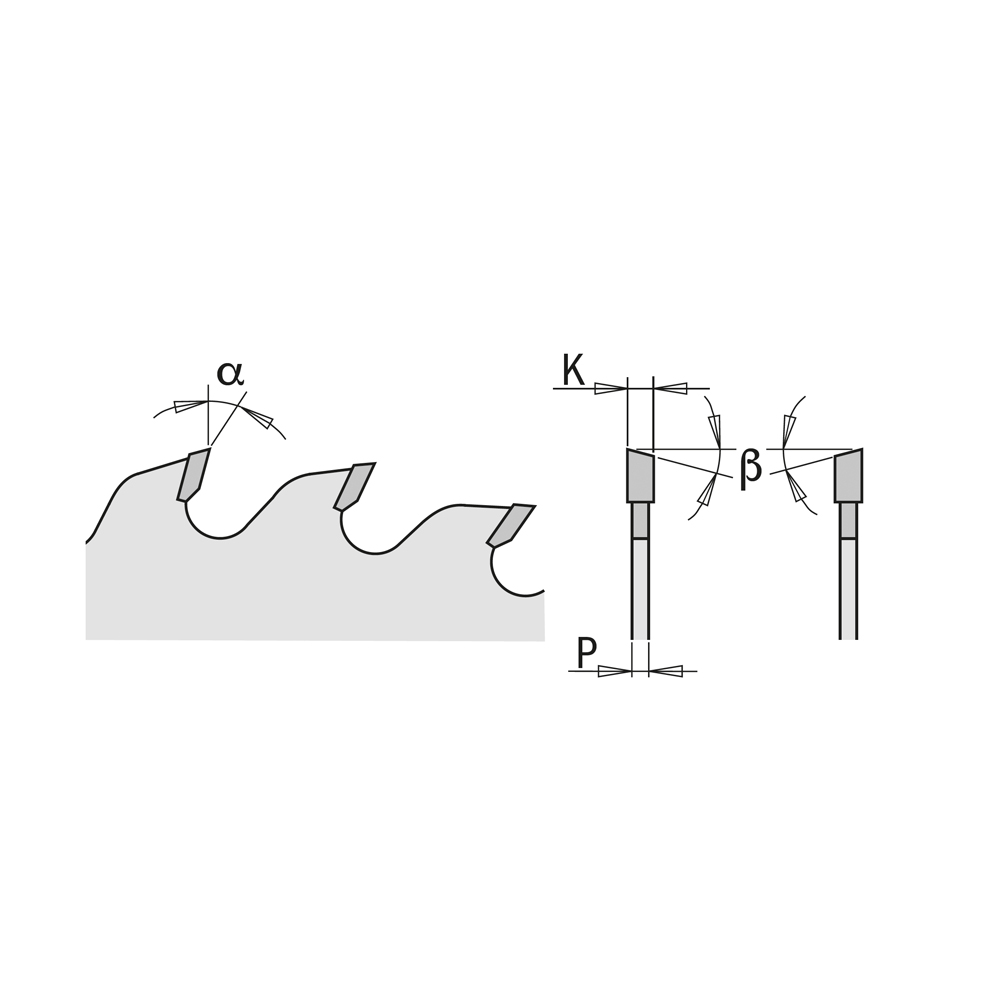

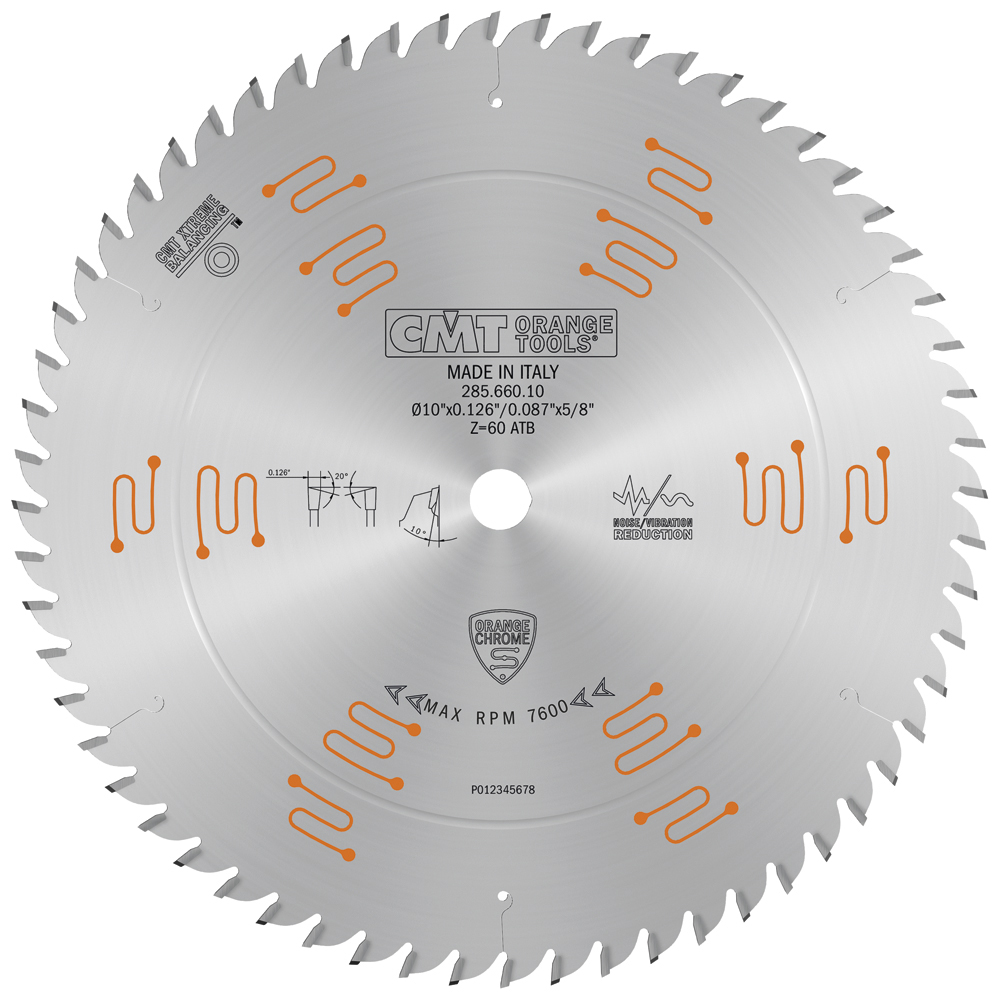

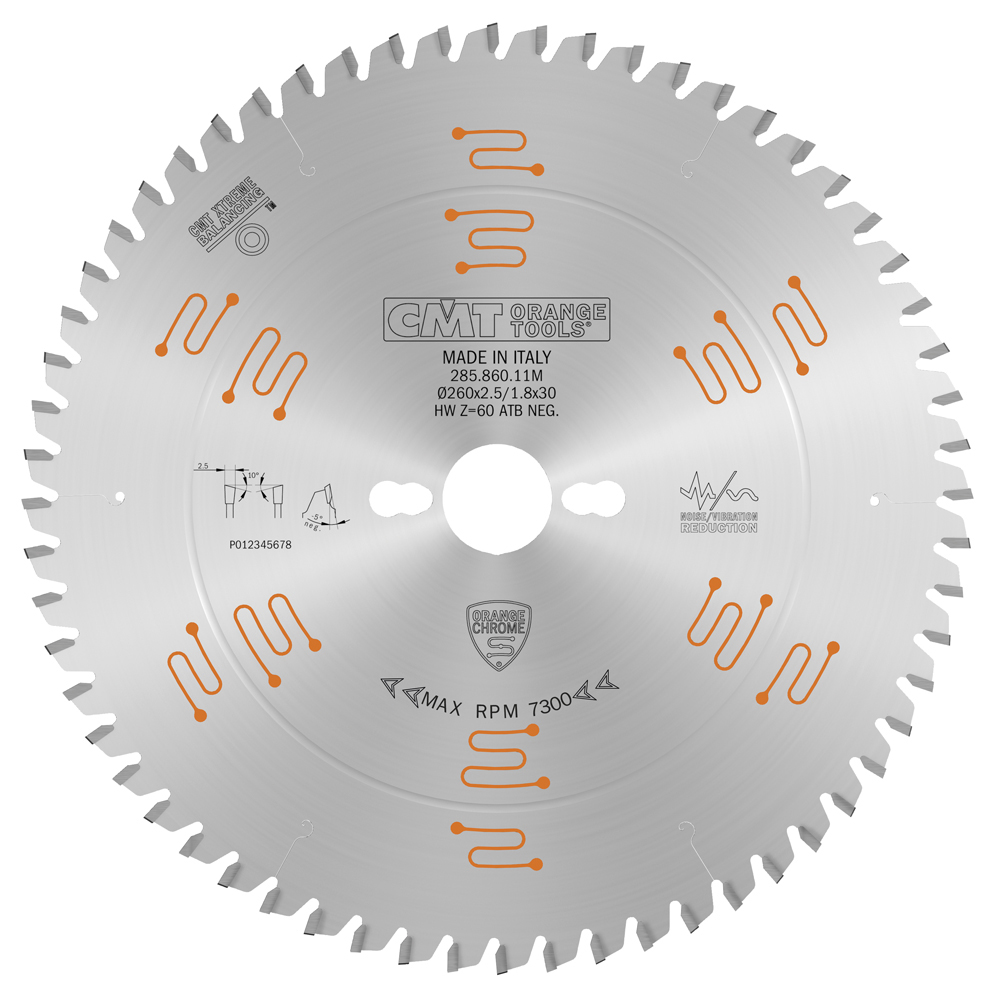

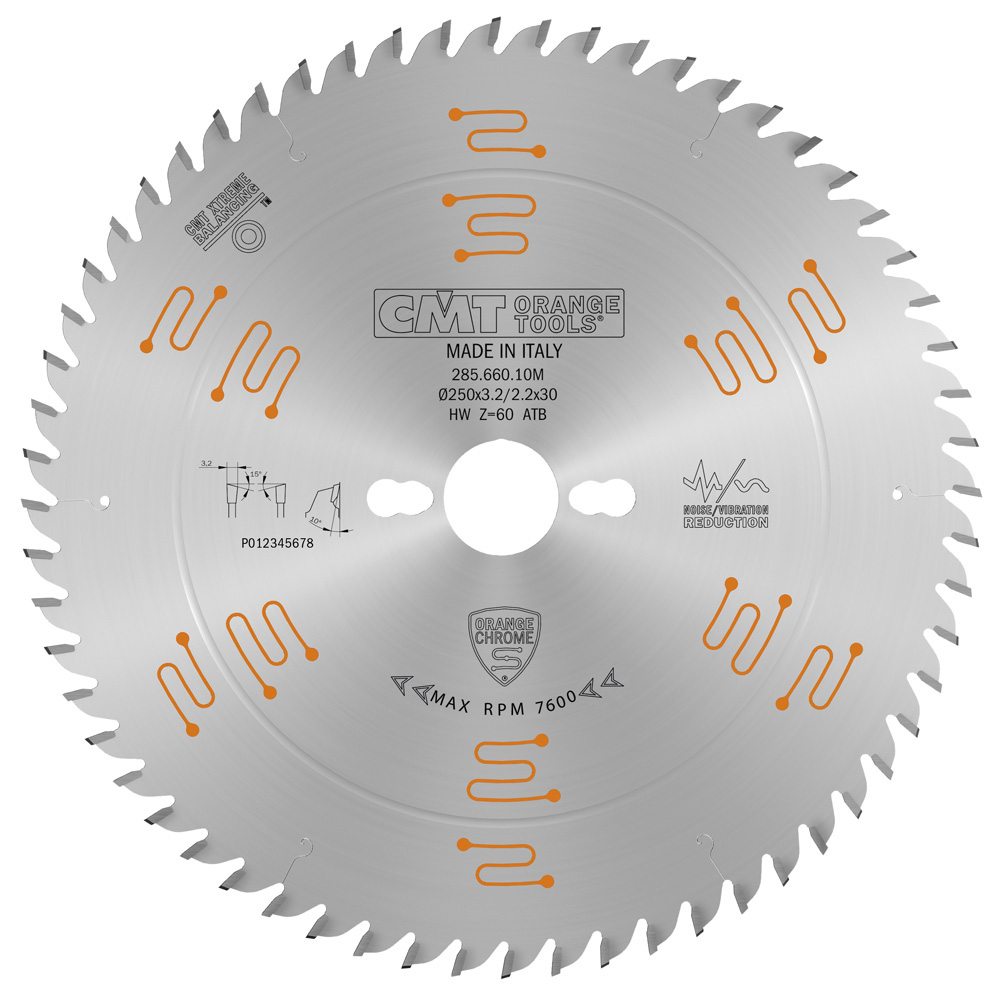

| Item Code | D | B | PH | Z | K | P | α | β |

|---|---|---|---|---|---|---|---|---|

|

285.816.48M

|

216 | 30 | 2/7/42 | 48 | 2.3 | 1.6 | -5 | ATB 15 |

|

285.816.60M

|

216 | 30 | 2/7/42 | 60 | 2.3 | 1.6 | -5 | ATB 15 |

|

285.825.48M

|

225 | 30 | 2/7/42 | 48 | 2.6 | 1.8 | 10 | ATB 15 |

|

285.660.10M

|

250 | 30 | COMBI3 | 60 | 3.2 | 2.2 | 10 | ATB 15 |

|

285.860.11M

|

260 | 30 | COMBI3 | 60 | 2.5 | 1.8 | -5 | ATB 10 |

|

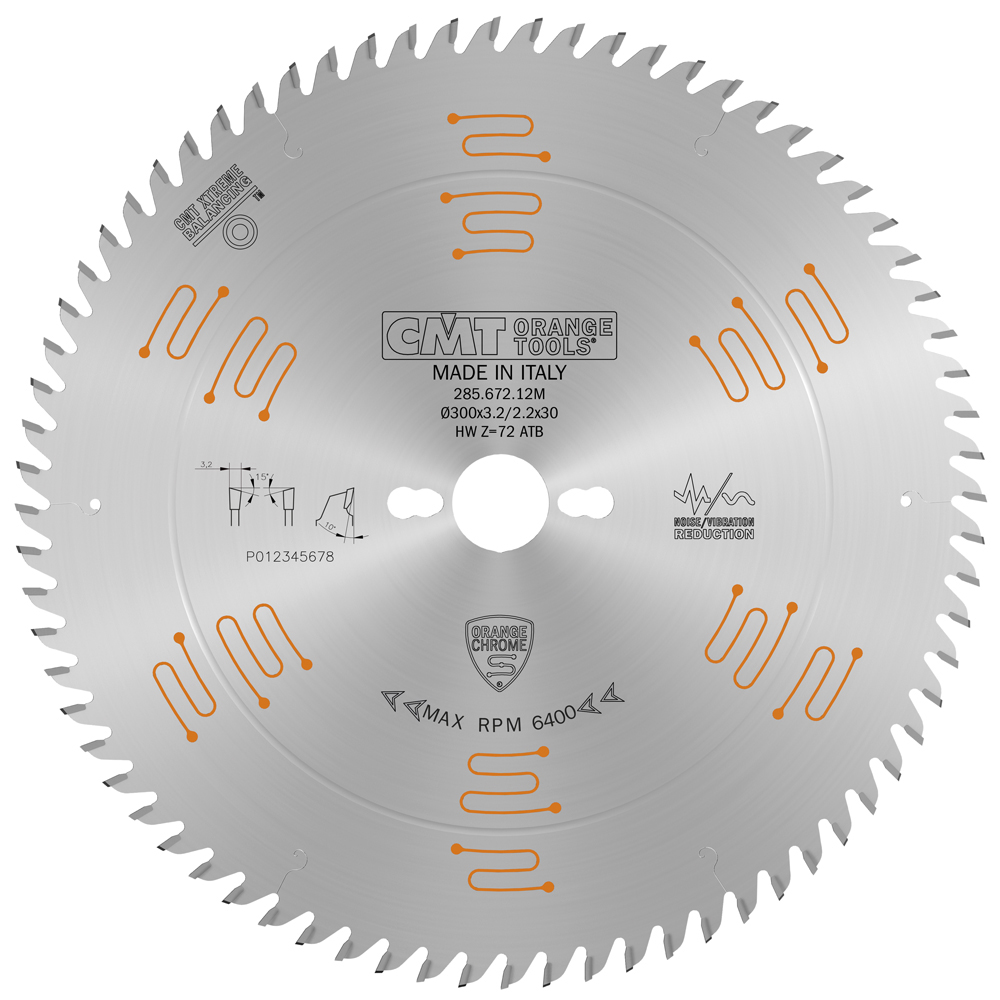

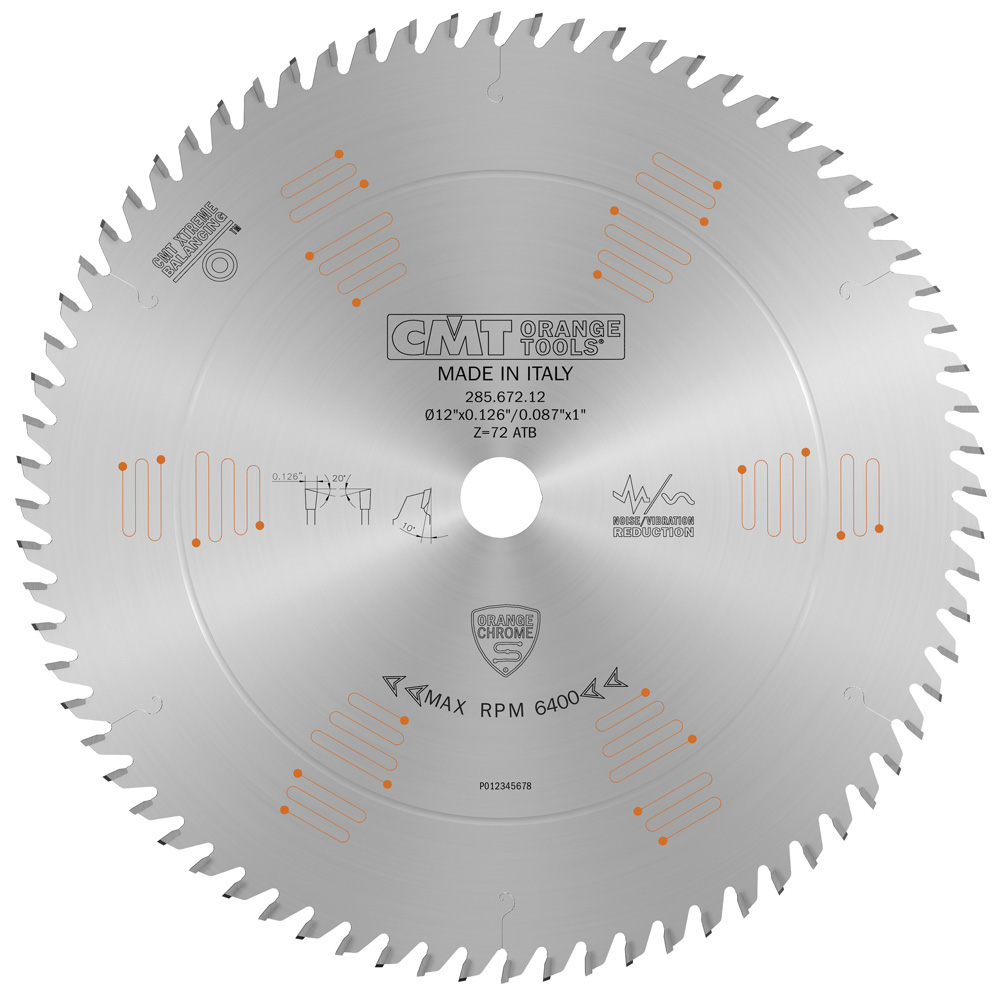

285.672.12M

|

300 | 30 | COMBI3 | 72 | 3.2 | 2.2 | 10 | ATB 15 |

|

285.684.14M

|

350 | 30 | COMBI3 | 84 | 3.5 | 2.5 | 10 | ATB 15 |

|

285.696.16M

|

400 | 30 | COMBI3 | 96 | 3.5 | 2.5 | 10 | ATB 15 |