ITK PLUS® circular saw blades ripping and crosscut - General Purpose - THIN KERF

271.ITKplus_rip_cros

|

|

LASER-CUT HIGH QUALITY STEEL PLATE BODY

Made with 44 HRC high quality steel and laser-cut to ensure longer life and precision cutting. |

|

|

LASER-CUT SOUND DAMPENING SLOTS

Slots reduce vibrations and noise by 10% compared to blades without it. *This feature improves cut quality and extends blade life. *In full compliance with National Noise Emission Standards and Regulations. |

|

|

SILVER BRAZING

Silver Alloy Brazing prevents carbide from breaking during the cooling process

and allows teeth to withstand high stress and impact especially when cutting harder woods and composite materials. |

|

INDUSTRIAL SINTERHIP HI-DENSITY CARBIDE

The SINTERHIP sintering process (Hot Isostatic Pressing) uses high temperature (up to 3500°F) and high pressure (up to 1500 psi) to fully consolidate carbide thereby resulting in a porosity-free product ensuring longer cutting life over traditional carbide and less risk of breakages. |

|

|

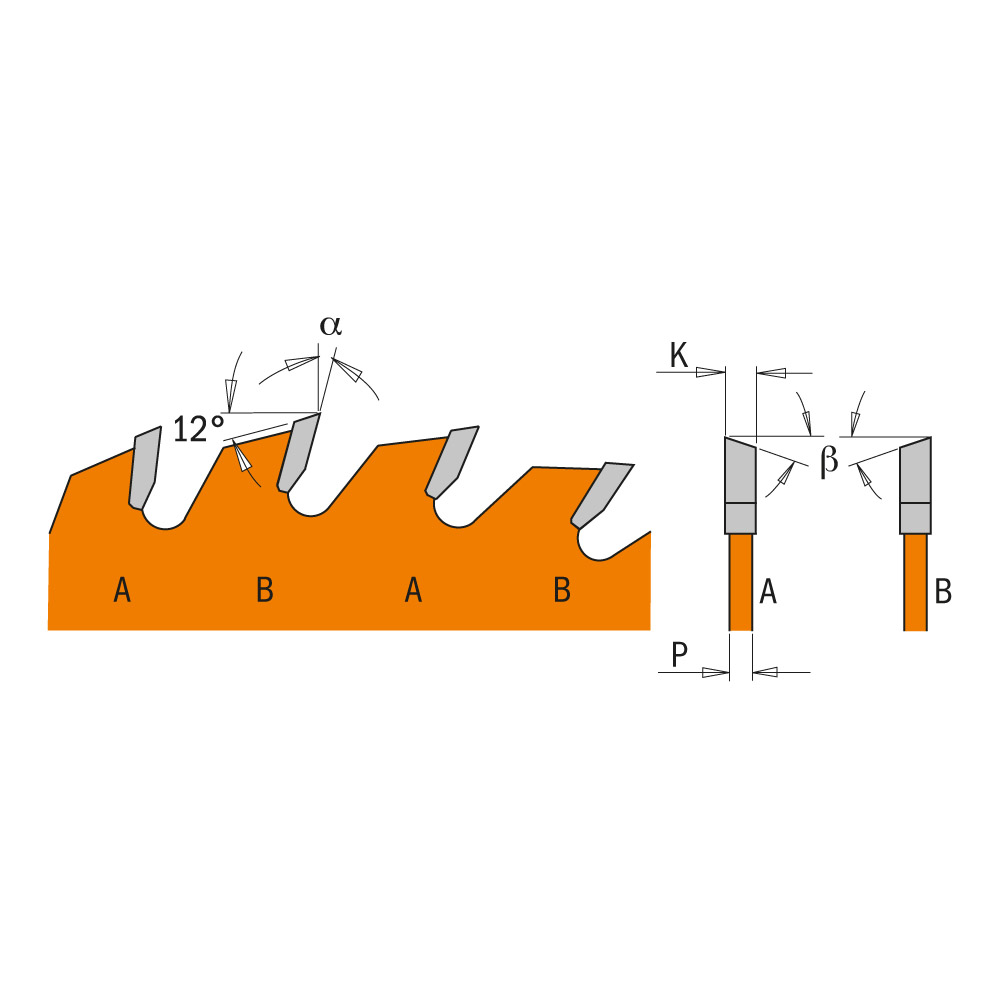

SHEAR ANGLE SHARPENING

The shear angle grinding, on the front face of the teeth, reduces the required cutting force thereby allowing for smoother cutting. |

|

ORANGE SHIELD® NON-STICK PTFE COATING

• Protects against corrosion and rust. • Reduces resin and residue build-up. • Reduces overheating and blade drag. • Improves performance and cutting life. |

Variations

Filter

| Item Code | D | B | PH | Z | K | P | β | α |

|---|---|---|---|---|---|---|---|---|

|

271.136.18H

|

136 | 20 (+10) | 18 | 1.5 | 1 | ATB 10 + SHEAR 8 | 20 | |

|

271.140.24H

|

140 | 20 | 2/6/32.5 | 24 | 1.8 | 1.2 | ATB 15 + SHEAR 8 | 15 |

|

271.150.24H

|

150 | 20 (+16) | 24 | 1.5 | 1 | ATB 10 + SHEAR 8 | 18 | |

|

271.165.24M

|

165 | 30 | 2/7/42 | 24 | 1.7 | 1.1 | ATB 10 + SHEAR 8 | 18 |

|

271.168.28H

|

168 | 20 | 2/6/32 | 28 | 1.8 | 1.2 | ATB 15 + SHEAR 8 | 15 |

|

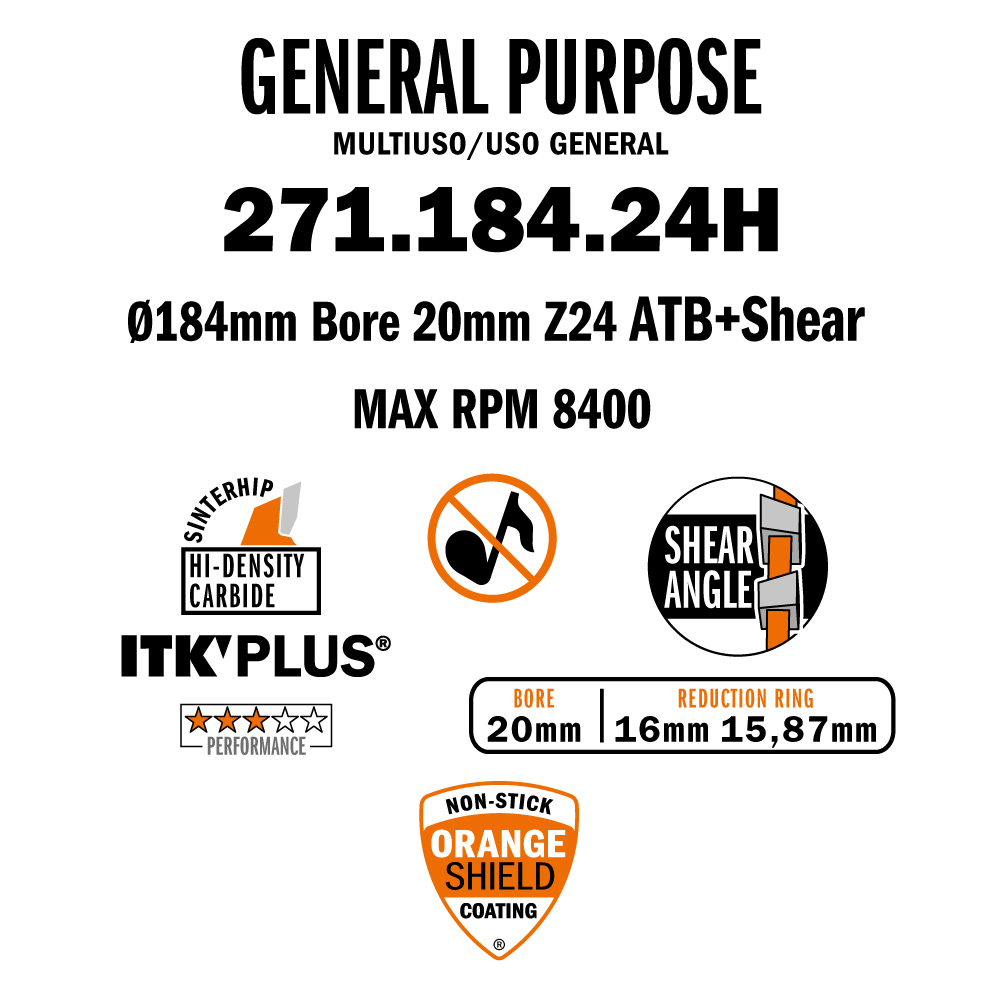

271.184.24H

|

184 | 20 (+16 +15.87) | 2/7/42 | 24 | 1.7 | 1.1 | ATB 10 + SHEAR 8 | 20 |

|

271.184.24M

|

184 | 30 | 2/7/42 | 24 | 1.7 | 1.1 | ATB 10 + SHEAR 8 | 20 |

|

271.190.24M

|

190 | 30 (+20 +16) | 2/7/42 | 24 | 1.7 | 1.1 | ATB 10 + SHEAR 8 | 20 |

|

271.200.36M

|

200 | 30 | 2/7/42 | 36 | 1.8 | 1.2 | ATB 10 + SHEAR 8 | 15 |

|

271.210.24M

|

210 | 30(+25) | 2/7/42 | 24 | 1.8 | 1.2 | ATB 10 + SHEAR 8 | 20 |

|

271.210.36M

|

210 | 30 (+25) | 2/7/42 | 36 | 1.8 | 1.2 | ATB 10 + SHEAR 8 | 15 |

|

271.216.36M

|

216 | 30 | 2/7/42 | 36 | 1.8 | 1.2 | ATB 10 + SHEAR 8 | -5 |

|

271.235.36M

|

235 | 30 (+25) | 2/7/42 | 36 | 2.4 | 1.6 | ATB 10 + SHEAR 8 | 18 |

|

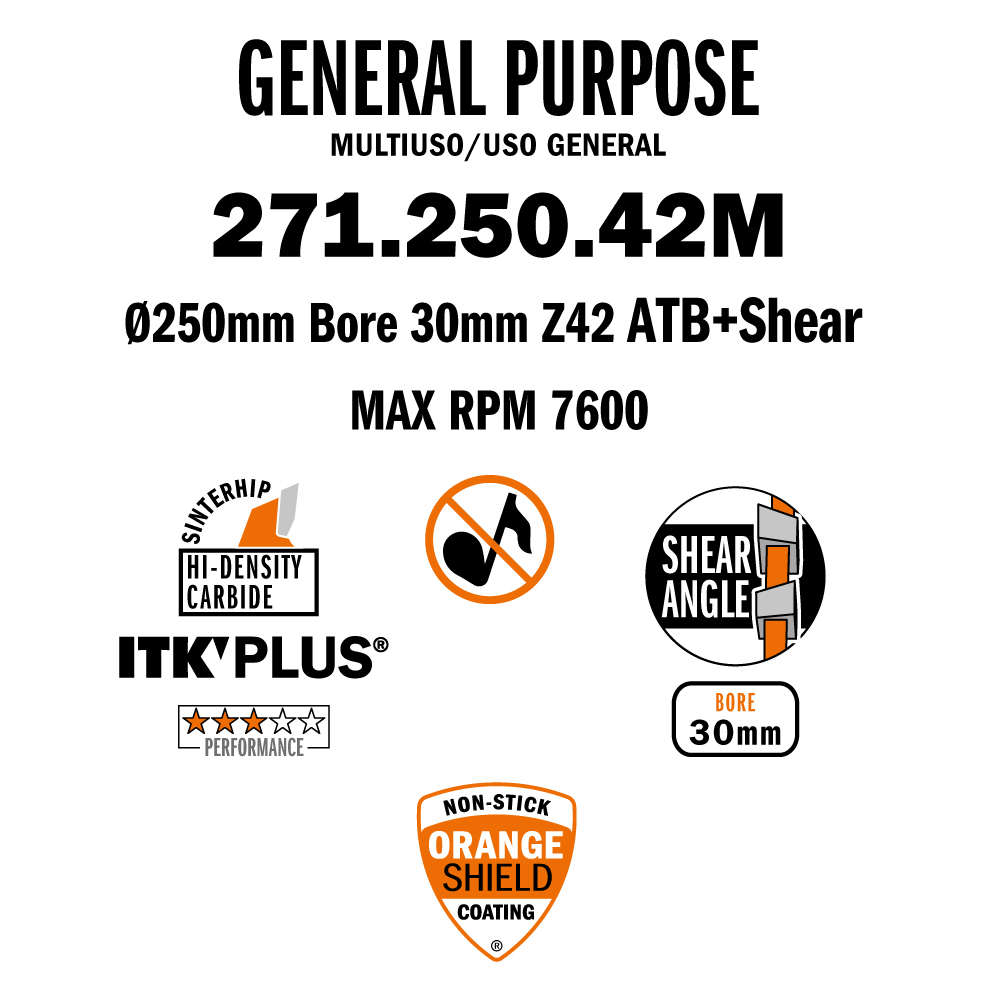

271.250.42M

|

250 | 30 | COMBI3 | 42 | 2.4 | 1.6 | ATB 10 + SHEAR 8 | 18 |

|

271.300.48M

|

300 | 30 | COMBI3 | 48 | 2.6 | 1.8 | ATB 10 + SHEAR 8 | 18 |

|

271.305.48M

|

305 | 30 | COMBI3 | 48 | 2.6 | 1.8 | ATB | -5 |

|

271.315.54M

|

315 | 30 | COMBI3 | 54 | 2.6 | 1.8 | ATB | -5 |