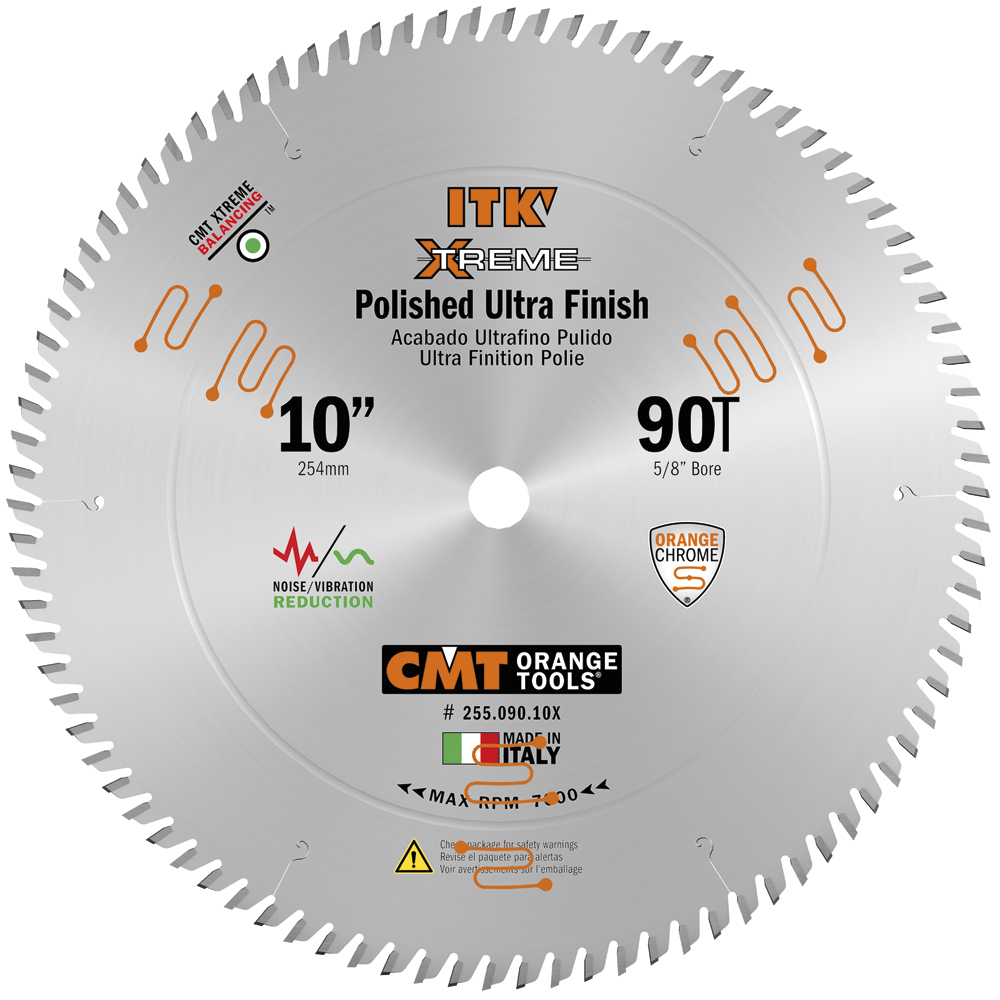

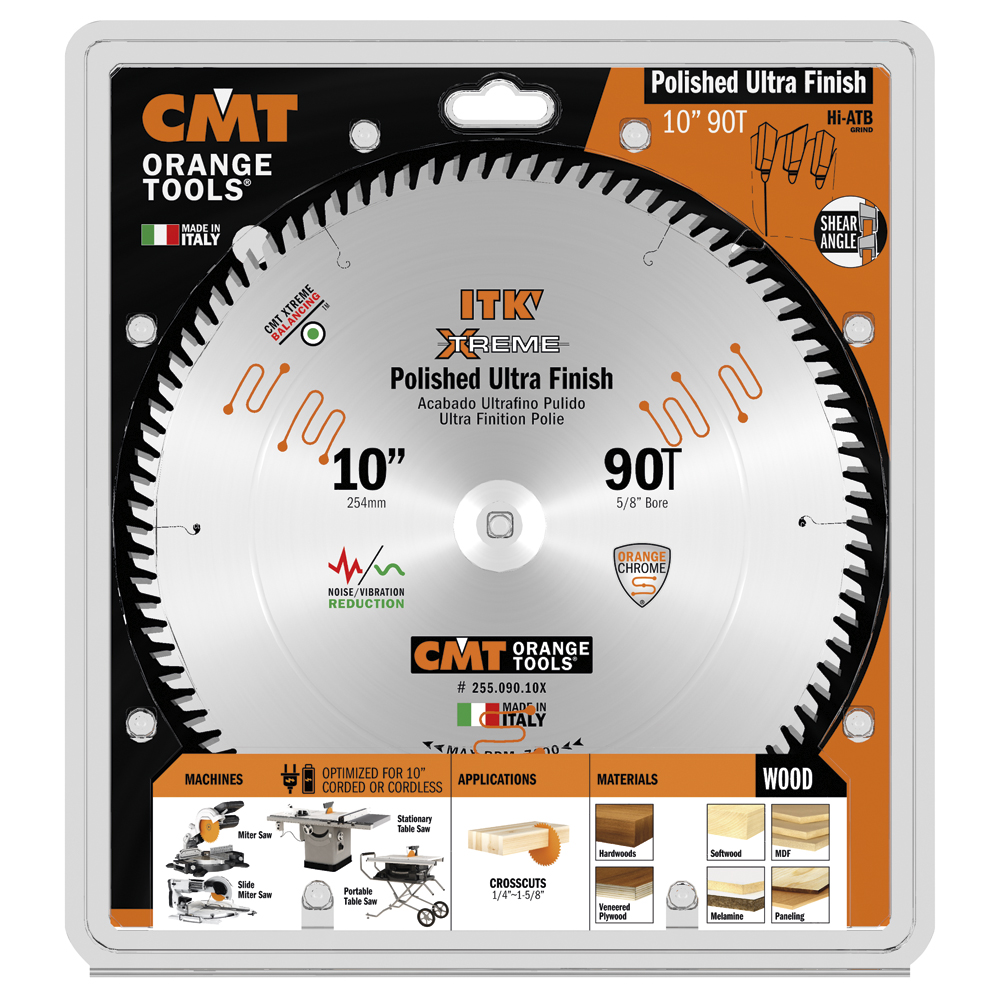

Polished Ultra Finish Saw Blade ITK-X HW

255X

.png) |

INDUSTRIAL CHROMIUM MICROGRAIN CARBIDE

Cutting teeth are made from a specially formulated chromium micrograin carbide which stays sharper longer by reducing cutting edge abrasion, improving cut quality and tool life. |

|

TRI-METAL BRAZING

The Silver-Copper-Silver tri-metal brazing process lets the teeth with stand severe impact caused by cutting harder wood and composite material. |

|

CHROME® COATING

Blade plate is covered with a chrome layer to protect your tool against corrosion and rust, guaranteeing longer tool life. |

.png) |

LASER-CUT HEAT EXPANSION SLOTS

Engineered to allow the blade to expand when heat build-up occurs from use, preventing blade warping. |

.png) |

Unique patented dynamic balancing several orders of magnitude above

and beyond that which is currently available in the marketplace. |

|

|

TENSIONING RING (10” and above)

A visible tensioning ring on the blade provides stability while cutting and perfect concentricity during rotation. |

|

PRECISION MIRROR FINISH SHARPENING

Each tooth is ground to razor sharp precision on a multi-axis CNC machine which creates perfect edge angle, guaranteeing extra-clean cuts and extended life. Featuring less than 0.25 μm Rmax in edge roughness. |

Variations

Filter