WARNING : Drilling, sawing, sanding or machining wood products can expose you to wood dust, a substance known to the State of California to cause cancer; Avoid inhaling wood dust or use a dust mask or other safeguards for personal protection. For more information go to www.P65Warnings.ca.gov/wood. WARNING: This product can expose you to chemicals including nickel and cobalt, which are known to the State of California to cause cancer and lead, which is known to the State of California to cause cancer and birth defects or other reproductive harm. For more information go to www.P65Warnings.ca.gov.

![[0, ]](/img/warning.png) California Proposition 65

California Proposition 65

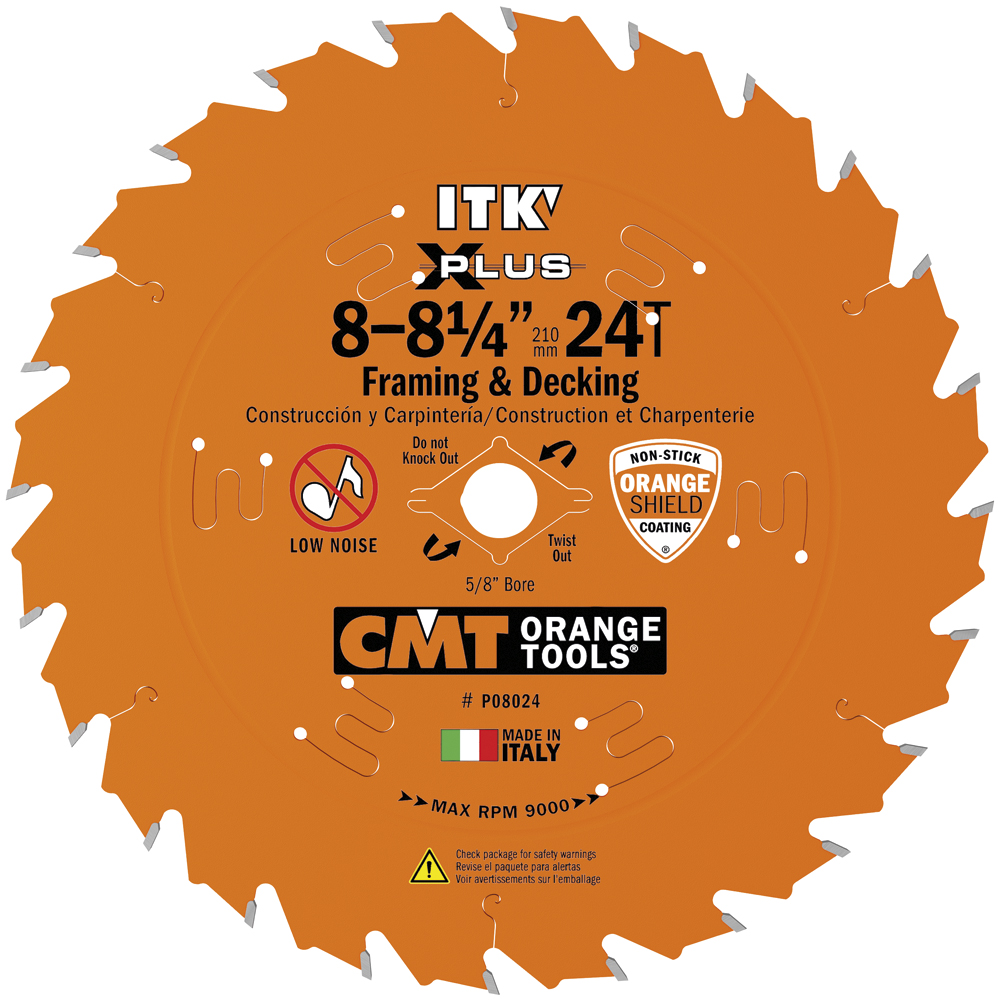

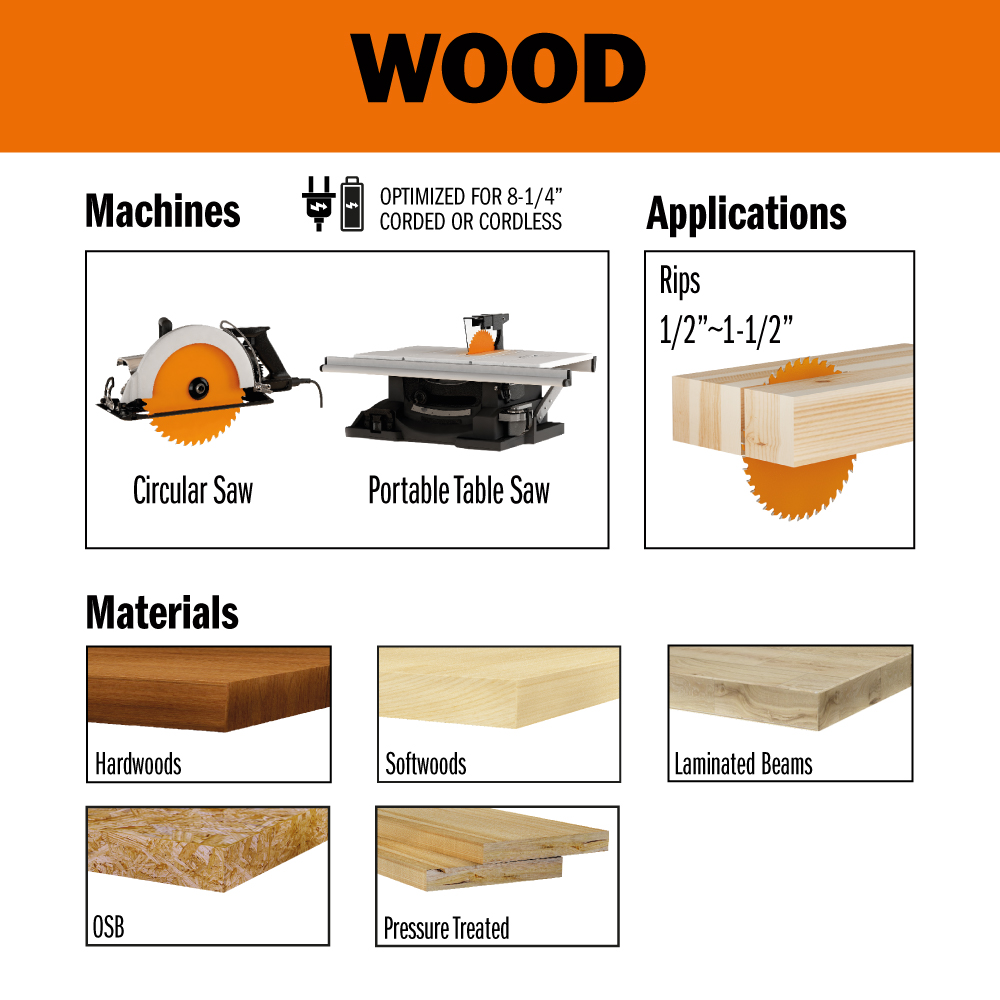

ITK XPLUS® Framing & Decking

P08024

|

ORANGE SHIELD® NON-STICK PTFE COATING

● Protects against corrosion and rust.

● Reduces resin and residue build up.

● Reduces overheating and blade drag.

● Improves performance and cutting life

|

|

LASER-CUT PREMIUM-QUALITY STEEL PLATE BODY

Made with 46-48 HRC premium quality harmonic steel from Germany and laser-cut to perfection providing tighter tolerances translating to longer life and accurate cutting ability. |

|

CMT XTREME BALANCING®

This system allows for extremely accurate dynamic balancing of the blade, several orders of magnitude above

and beyond that which is currently available in the marketplace. INT. PAT. PEND. |

|

|

BODY FLATNESS

Blade body flatness obtained via special straightening processes that guarantee exceptional tolerances.

|

|

|

TENSIONING RING

A visible tensioning ring on blade body provides stability during the cut and perfect concentricity during rotation. For improved performance, tensioning is fine-tuned according to machine/application. |

|

THIN-KERF DESIGN

Thin-kerf blades are ideal for cordless circular saws because they consume less power, extending battery life, and enable higher cutting speeds, improving efficiency. |

|

INDUSTRIAL CHROME CARBIDE

Cutting teeth are made from a specially formulated chromium micrograin carbide which stays sharper longer by reducing cutting edge abrasion, improving cut quality and tool life. |

|

TRI-METAL BRAZING

Silver-Copper-Silver Tri-Metal Brazing prevents carbide from breaking during the cooling process and allows teeth to withstand high stress and impact especially when cutting harder woods and composite materials. |

|

PRECISION MIRROR FINISH SHARPENING

Each tooth is precision ground on a multi-axis CNC machine creating perfect edge angles that provide extra-clean cutting performance and extended life. Featuring less than 0.25 µm Rmax in edge roughness. |

|

|

LASER-CUT HEAT EXPANSION SLOTS

Engineered to allow the blade to resist deformation from increases in temperature due to cutting applications and centrifugal forces. |

Variations

Filter

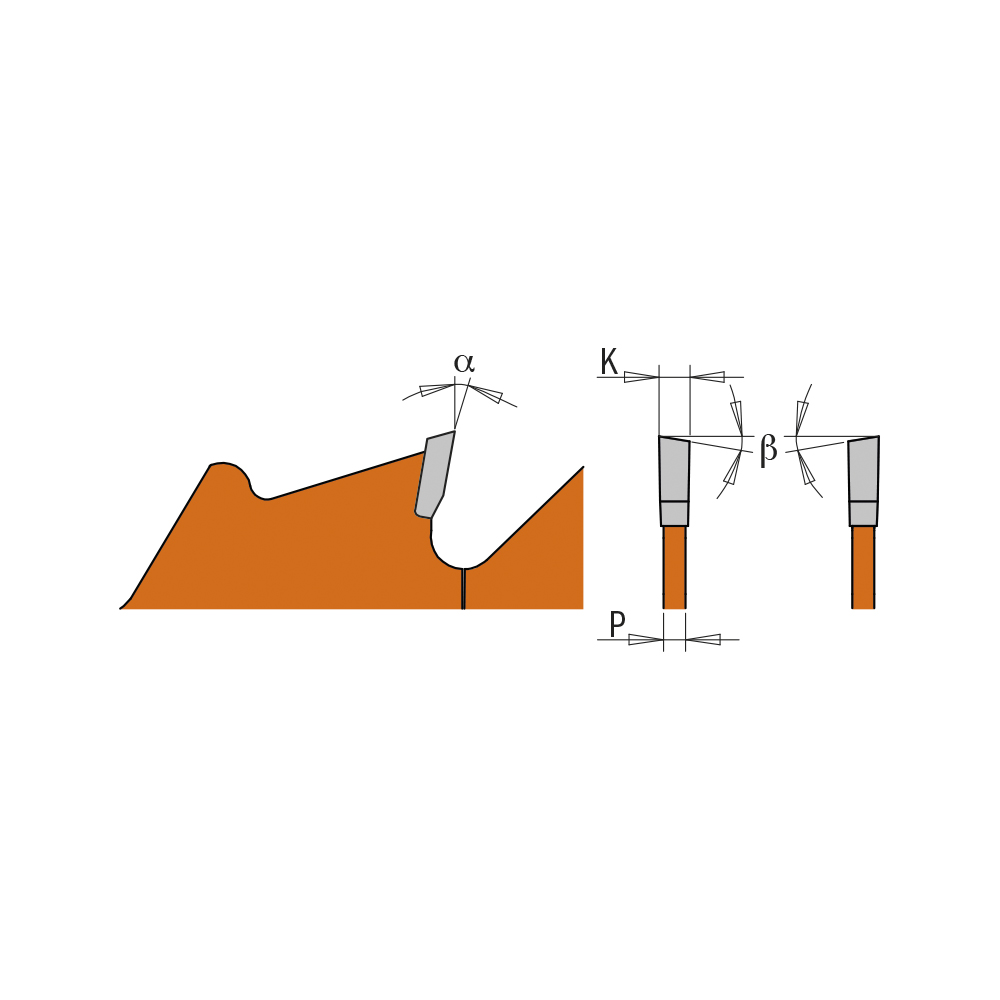

| Item Code | D | Z | B | β | K | P | α | |

|---|---|---|---|---|---|---|---|---|

|

P08024

|

8-8-1/4 | 24 | 5/8 | ATB 15 | 0.082 | 0.047 | 20 |