![]()

WARNING : This product can expose you to chemicals including nickel and cobalt, which are known to the State of California to cause cancer and lead, which is known to the State of California to cause cancer and birth defects or other reproductive harm. For more information go to www.P65Warnings.ca.gov.

WARNING : This product can expose you to chemicals including nickel and cobalt, which are known to the State of California to cause cancer and lead, which is known to the State of California to cause cancer and birth defects or other reproductive harm. For more information go to www.P65Warnings.ca.gov.

![[0, ]](/img/warning.png) California Proposition 65

California Proposition 65

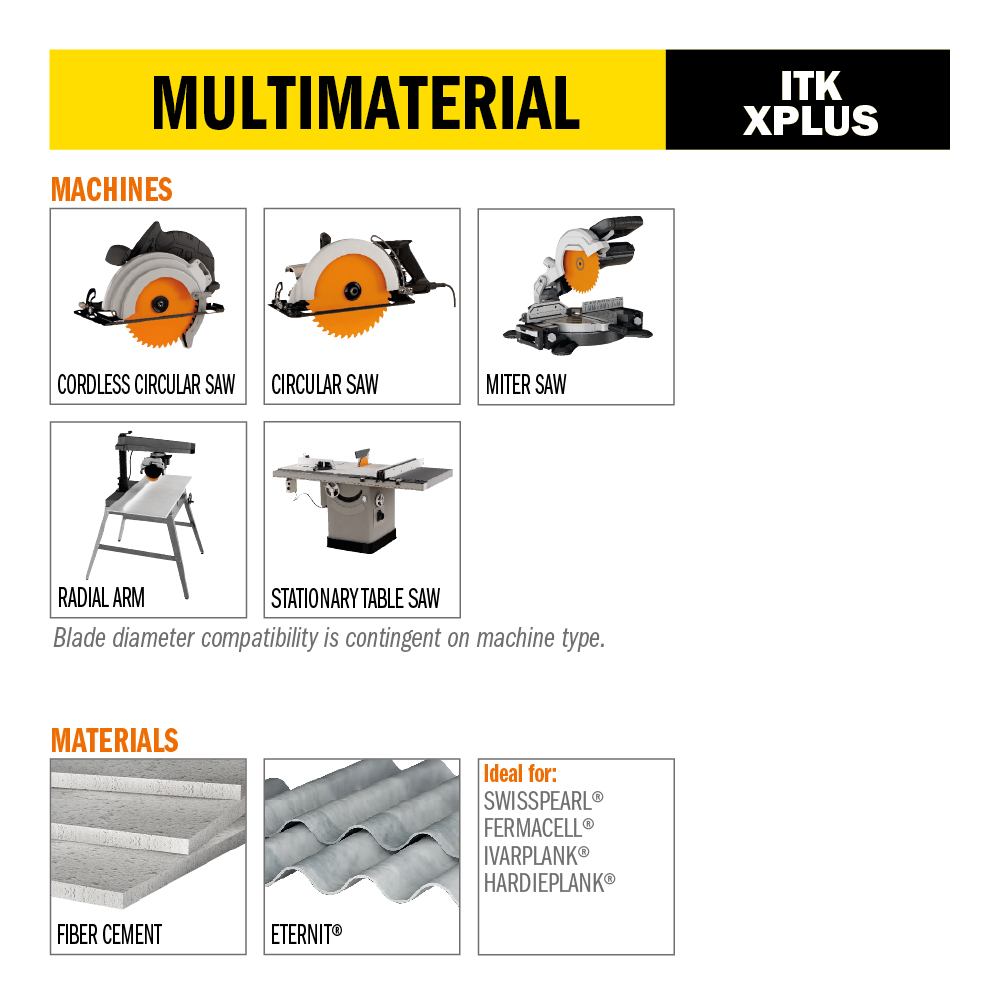

ITK Plus® diamond circular saw blades for ultra-hard materials

236

|

INDUSTRIAL SINTERHIP HI-DENSITY CARBIDE

The new process SinterHIP (high temperature 3500°F and high pressure 1500 psi) creates a porosity-free and Hi-Density carbide which provides a longer cutting life than tradition carbide. |

|

TRI-METAL BRAZING

The Silver-Copper-Silver tri-metal brazing process lets the teeth with stand the severe impact caused by cutting harder woods and composite material. |

|

NON-STICK ORANGE SHIELD® COATING

Keeps the blade running cool, reduces pitch build up and protects against corrosion. Ideal for all types of wood including wet lumber. |

|

|

LASER-CUT HEAT EXPANSION SLOTS

Engineered to allow the blade to expand when heat build-up occurs from use, preventing blade warping. |

.png) |

Unique patented dynamic balancing several orders of magnitude above

and beyond that which is currently available in the marketplace. |

|

|

TENSIONING RING (10” and above)

A visible tensioning ring on the blade provides stability while cutting and perfect concentricity during rotation. |

|

PRECISION MIRROR FINISH SHARPENING

Each tooth is ground to razor sharp precision on a multi-axis CNC machine which creates perfect edge angles, guaranteeing extra-clean cuts and extended life. Featuring less than 0.25 μm Rmax in edge roughness. |

Variations

Filter

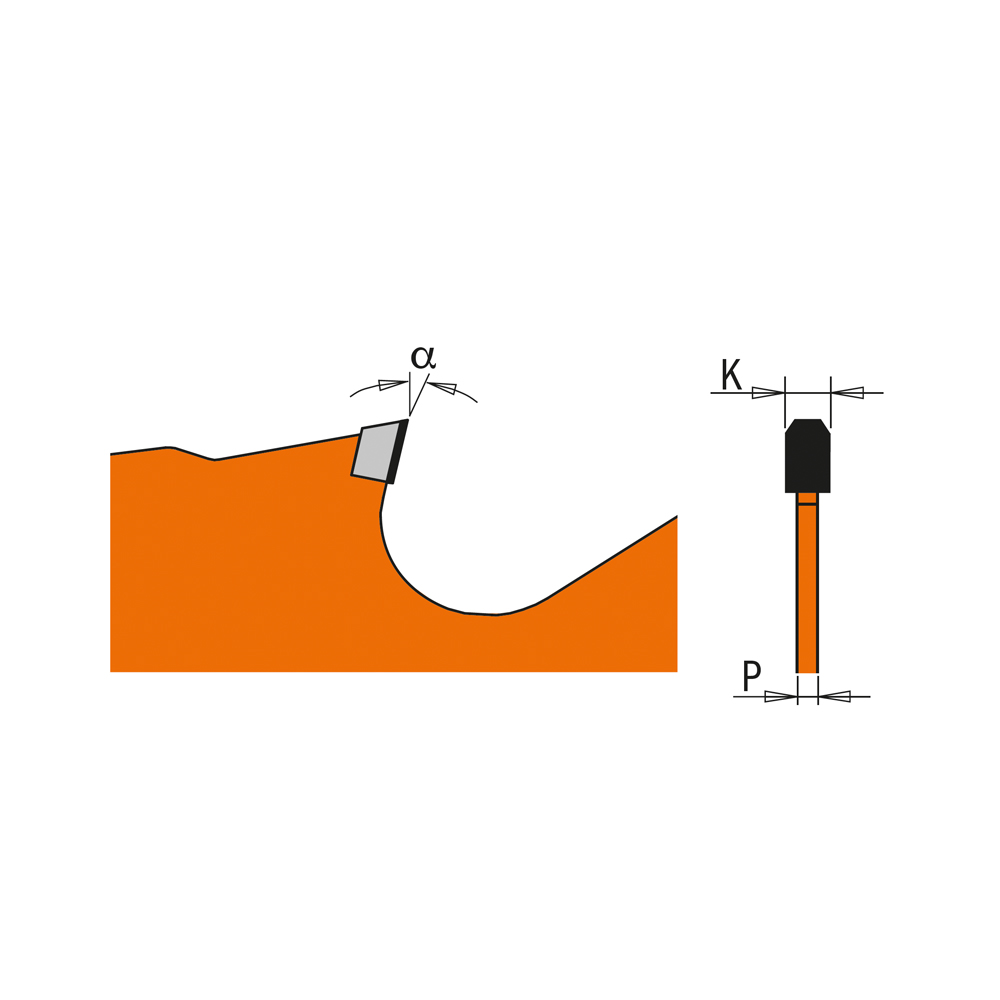

| Item Code | D | B | Z | K | P | β | α | MAX RPM | |

|---|---|---|---|---|---|---|---|---|---|

|

236.004.06

|

6-1/2 | 5/8 | 4 | 0.071 | 0.055 | TCG | 12 | 9.500 | |

|

236.004.07

|

7-1/4 | 5/8 | 4 | 0.071 | 0.055 | TCG | 12 | 8.300 | |

|

236.004.07-X10

|

7-1/4 | 5/8 | 4 | 0.071 | 0.055 | TCG | 12 | 8.300 | |

|

236.006.10

|

10 | 5/8 | 6 | 0.087 | 0.064 | TCG | 12 | 7.600 | |

|

236.008.12

|

12 | 1 | 8 | 0.087 | 0.064 | TCG | 12 | 6.400 |